Their experience is unsurpassed with a reputation of being the preferred supplier in this major growth area. World class chickens, cutting edge processing technologies and state of the art chilling facilities ensure the highest standard for their customers.

With a wide and varied range of products from fresh whole birds, cuts and portion controlled fillets, to kebabs and schnitzels, ABD Poultry identified that they needed a solution to their packing needs. Productivity throughput was low and the finish of the hand wrapped product became inconsistent. Staff were manually wrapping, weighing and labelling.

In order for the business to grow and meet the standard and expectations their product was renowned for, ABD realised they needed to automate this process, they approached Heat and Control for their weighing and packaging solutions.

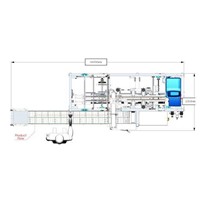

On January 20, Heat and Control installed an Ishida WM-Nano into ABD's processing facility.

The WM-Nano is the ideal solution for retailers, grocers, markets and butchers with limited space needing high performance and consistent weighing, wrapping and labelling.

The WM-Nano employs power and flexibility, with colour touch screen, integrated printer and Wi-Fi to provide wireless data communication all wrapped up in one super table-top wrapper. The generous in-feed accommodates trays up to 9 inches x 11 inches, wraps up-to 3kg packs, and uses PVC wrapping film in widths from 400 to 500mm.

With these features, the benefits of the WM-Nano meant improved packaging appearance and automation, better time management and productivity.