Flexible pneumatic Airstroke® air spring actuators from Firestone – including compact and easily installed Style 16 types - adjust to different load requirements simply by varying the air pressure contained within them.

These tough rubber-and-fabric bellows (identical in construction to the airbags proven in truck and train suspensions) are suitable for applications requiring flexible force and continuously supple performance to flex with irregular loads.

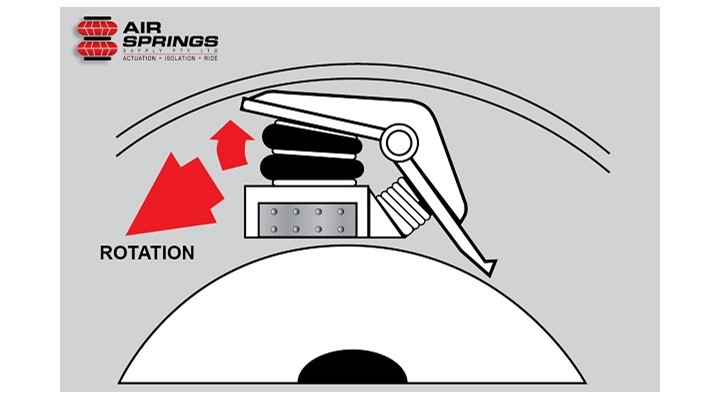

“Airstroke air springs provide force evenly over the surface upon which they are acting, rather than imposing sharp point loads. Further, they will undulate over irregular loads passing beneath them, flexing with the load profile if necessary, rather than fighting irregularities in the load and causing jerking, jamming and strain on the production line,” says Air Springs Supply National Sales and Marketing Manager Mr James Maslin.

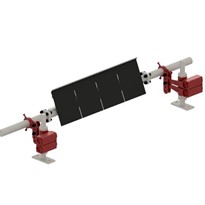

By preventing material buildup, belt scrapers help keep the belt from drifting off track, prevent erratic loads on the motor, eliminate uneven wear on pulley bearings and damage to return idlers, as well as helping to minimize belt stretching.

Suitable for uses as diverse as fine food and pharmaceutical production, through to mineral processing and bulk material handling, air springs also have another major advantage for design engineers: the ability to rotate through an angle without a clevis. In addition to making air springs easy to install in compact spaces, this ability to bend with load (and to tolerate side loadings within certain limits) means the air springs will perform where more rigid alternatives would break or wear.

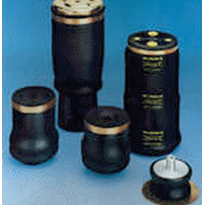

Airstrokes suitable for belt scrapers include the Model 16 single convoluted models, with stroke of 35mm (1.4in), and low collapsed (starting heights) of just 48mm (1.9 in) make them easy and compact to install. Producing up to 6.93 kN at 7 BAR, they run off normal factory air. The Style16 Airstroke actuators are part of an extensive range of single, double and triple-convoluted air springs available in force capacities from a few dozen kilograms up to 40,000kg a unit, with strokes up to 350mm.

Air springs’ advantages (such as containing no internal moving parts to break or wear) have been widely proven over a wide range of materials handling uses.

These extend from conveyor direction gate actuation, lift sections and bumper stops, through to stamping presses, gluing presses and flexible counter-pressure cushions for automotive body component presses (where, again, they are valued for their ability to increase production quality by applying force evenly over the surface to which they are being applied).

“In the current industrial environment – where maximum output and minimum downtime is vital – Airstrokes provide a simply engineered option for companies seeking major improvements without major cost,” said Mr Maslin.