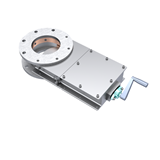

In pumping applications, the head loss (pressure drop) across valves is also an important factor to be considered. UVE's range of SLURRYTUFF™ ball check valves employ a free moving ball, which unseats to permit flow in one direction, but seals against a seat to prevent backflow.

The slurry ball check valve meets these requirements by providing:

- positive back flow prevention,

- minimum maintenance and

- low friction losses.

UVE's slurry ball check valves offer great operational reliability because of their construction and working principle. Its construction consists of just three components namely the body, the cover and the ball. (The ball is the only moving part)

The SLURRYTUFF™ check valve keeps solids, stringy material, grit, rags, etc. moving without the need for back flushing. The ball rolls clear of the water way providing "full flow" equal to the nominal size.

There is no place for stringy material to wrap around and no pockets for sediment to collect. It is basically a non-clog check valve. There are no outside levers, weights, springs, dash pots or other accessories needed to correct the deficiencies of the swing check valve.

The ball is hollow metal with an exterior coating of urethane, which is resistant to tearing and abrasion, grease, petroleum products, animal and vegetable fats, dilute concentrations of acids and alkali's (PH 4 - 10), has a high load bearing capability and low compression set. The ball rotates and thus seats on a different portion of its surface each time. These features prevent excessive wear and deterioration, therefore, assures a long useful life without costly maintenance and down time.

Since the ball is only slightly heavier than the media, the energy needed to move the ball to full open position is small compared to that necessary to lift a clapper, lever, weight (or spring) plus bearing and packing friction of a swing check valve. Net result is less head loss (pressure drop) through a SLURRYTUFF™ check valve.

The following advantages make UVE's SLURRYTUFF™ ball check valves extremely suitable for use in slurry, sewage and dirty water systems:

- Reliable operation without the danger of clogging

- Efficient operation even with small pressure differences

- Low slam (hammer) characteristics

- No wear under normal conditions

- Maintenance-free and long life

Valves may be installed vertically or horizontally. Various types of coatings and ball elastomers are available to suit the most extreme of applications.