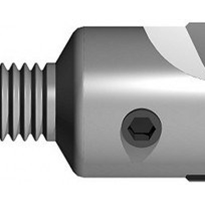

The new way is forming countersink tool for the punch press is made to your specifications and produces a clean countersink in seconds. It eliminates the labor-intensive drill and deburr operations. This cuts your production time by 50% or more.

Two approaches to attractive and quick countersinks

- A coining countersink tool is ideal for thicker material because it presses the material into the final shape. These excel at holding a tight hole tolerance. Available to form down, with interchangeable inserts for fast size changes, and in the self-stripping form-up style.

- A forming countersink tool works best on thinner materials as it bends the material into the hole to create the "sink." Like coining countersink tools, these are available to form down with interchangeable punch-tip inserts for cost savings and flexibility and in the self-stripping form-up style.

Watch the video below to see Wilson Tool countersinking tool punches a countersink without the need for a secondary operation. Countersinking is done quickly and precisely in one stroke of the punch.