The Challenge

- No pump lasted longer than two weeks in service

- Copper concentrate is highly abrasive, dense SG is 1.4

- Bobcat and man used – expensive

The Discflo Solution

- ‘Boundary layer effect’ and rubber lining reduces abrasive wear

- Run 5 months with no downtime

- Disc pump’s ‘viscous drag principle’ good for dense fluids

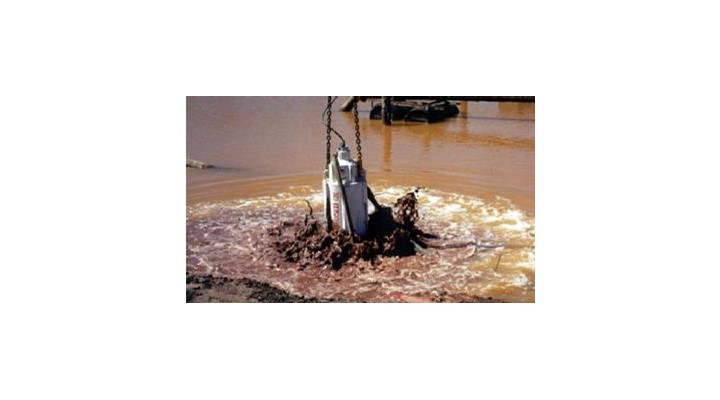

A specially designed Disc pump at the Broken Hill mine in New South Wales is being used to pump a highly abrasive and dense copper concentrate. It has been operating for five months continuously (reported in June 1998), beating all previous pumps’ performance. Copper concentrate is a remarkably difficult material to pump. It contains ultra fine, highly abrasive particles, and is extremely dnese with a specific gravity of 1.4. pasminco tried a number of different pumps before finding the Disc pump but all failed within two weeks or less of service due to abrasive wear. Prior to installing the Discflo pump, they used a bobcat and manual labor to move the concentrate.

The Discflo Disc pump used at Pasminco is a combination of a 604 and a 403- 2HHD, and has been rubber-lined for extra abrasive protection. The first prototype was designed and tested last year by George Fyfe of Transco, Discflo’s distributor in Australia. The first production model was installed at the start of the year (1998) and has run without any downtime since then, pumping 500 GPM at 35 ft TDH. Pasminco plans to purchase another Disc pump for a similar application at its mine in Hobart, Tasmania. This pump will also be designed and installed by Transco Manufacturing.

Call Discflo now to find out how our pumps can solve your problems.