The importance of using the correct glove

Selecting the right glove can have three direct benefits for a food processing operation:

1. Ensures that the food is safe and hygienic

Using the appropriate glove during food processing can protect against the risk of contamination as well as the spread of food-borne pathogens. As an example there are many food processing industries that favour a conspicuous blue glove as the glove is easy to identify if any glove particles accidentally contaminate the product.

2. Improves employee safety and productivity

Those who work or visit food processing areas can be exposed to a number of hazards including sharp-edged instruments or surfaces, extreme temperatures, grease, bacteria, harsh chemicals used during cleaning or even the foods themselves. Having the right glove to suit each application can minimise the potential for accidents, which has a positive flow-on effect on productivity levels. The correct glove will also result in comfort for the wearer.

In some instances workers are required to wear 2 or even 3 pairs of gloves at once to protect against each element of the food processing operation. E.g. someone working in a cold environment or with meat might need to wear a poly/cotton glove for warmth, in addition to a cut-resistant glove and a non-slip outer glove to protect from liquids or greases.

3. Reduces costs to the company

Using the incorrect glove during food processing can result in the food being contaminated, or workers being injured. Each of these outcomes incurs a direct cost to the company whether through the loss of inventory, cost of replacement, poor reputation amongst customers, labour costs and possible compensation or rehabilitation costs. Getting it right the first time will reduce the risk of these costs and improve productivity.

Selecting gloves based on material

One of the most straight forward ways to ensure you are using the right glove is to decide based on the glove's material. With the latest technology there are many different materials available, each providing benefits for specific food processing applications.

Cut-resistant gloves

There are many different fibres and materials used for cut-resistance. Some of the most common include cotton, Kevlar®, high performance polyethylene and stainless steel mesh. There are also coated gloves that can provide sufficient cut resistance.

Temperature protection gloves

The best materials for protecting against hot or cold environments are made from cotton, cotton terry, Kevlar® yarns and poly/cotton blends. For keeping hands warm, dry and protected from abrasions try using a vinyl coated, foam insulated glove.

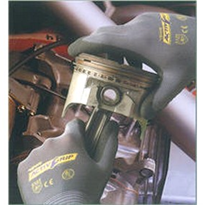

Gloves required for gripping

For slippery or wet surfaces it is ideal to use gloves with a raised pattern or a textured/embossed surface as these will provide a higher level of grip. These kinds of gloves are generally made from natural rubber latex, nitrile or blended materials.

Heavy duty gloves

For heavy duty gloves it is best to select gloves that are made from natural rubber latex, nitrile rubber, neoprene coated or vinyl coated as these are designed to protect the wearer from chemicals and cleaning solutions. These gloves can also have cotton lining for enhanced wearer comfort and temperature protection.

Disposable gloves

The ideal materials for disposable gloves include natural rubber latex, nitrile, polyvinylchloride (PVC) or vinyl. These materials are used due to their highly dexterous nature while some gloves also have a polymer or powdered coating to assist with donning and doffing.

There are other important facts to consider when choosing the right glove. For more product tips or a recommendation on your application contact a trusted glove supplier.

This guide to food processing gloves is supplied by Signet and Ansell Industrial Healthcare.