In collaboration with Coalpac Contractor Absolute Earthmoving Repairs, heater jackets were supplied to warm grease in an IBC and on the mine service truck.

Frustration with freezing pumps and viscous grease led the Maintenance Supervisor at Cullen Valley Mine on a hunt for a solution.

He wished to warm high viscosity grease in an IBC and then pump it at night onto a Service Truck for use during the day in the Mine to service and maintain equipment.

The grease had to be pumped at night from the IBC into the onboard grease tank as this was the only time the truck was available to do so. In his search he came across SBH Solutions who were only too willing to assist with the project.

SBH Solutions is so confident in the LMK Thermosafe product line (assuming validation of requirements verses capability) that it offers trial-before-you-buy on a number of heaters.

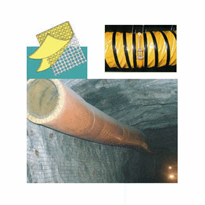

In this case, Cullen Valley Mine was able to trial the 1300w IBC1 heater with insulated lid on its IBC greasetainer, and also trial a 1000w HHD drum heater jacket around its custom sized Service Truck tank.

"The Service Truck grease tank was slightly bigger in circumference than a standard drum but the heater straps were able to bridge the gap—good enough for a trial," Nigel Smalls of SBH Solutions said.

The trials were successful and the operational method outlined by the Maintenance Supervisor confirmed. A custom heater for the tank was ordered.

There was however one issue to deal with—wet weather and dust exposure.

The heater jackets are not designed for continual exposure to the elements, so a standard heavy duty cover was bought for the IBC and a custom "oversock" was designed for the tank to include covering the top mounted grease pump.