Across the world in the same period there have been 5 ‘recorded’ fatalities and over 200 recorded serious injuries.

Belly plates on large equipment such as dozers typically weigh hundreds of kilos and are prone to accumulating debris over the course of their normal operations, which increases their weight further and obscures the critical components that secure them in position.

With traditional belly plate removal techniques, there is a high risk of crush injuries, as the mechanic has to crawl under the vehicle to line up the bolt holes. These vehicles are often large dozers weighing tens of thousands of kilograms, with belly plates that weigh If the plate is not appropriately restrained or supported, uncontrolled movement can occur when loosening nuts or bolts, which poses a huge safety risk if a mechanic is working directly underneath 500kg of steel.

If a dozer needs servicing while still in the field, other problems can occur, such as poor lighting, poor ventilation or inadequate space. These create significant hazards for a mechanic who needs to be positioned underneath the dozer to carry out maintenance.

SOLUTION

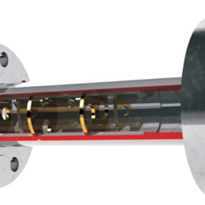

The belly plate can be locked, secured or restrained, but the biggest safety concern is still having the mechanic placed directly underneath the dozer, or heavy vehicle. Safety MITS’ TED (Tracked Elevating Device) is the ideal solution that eliminates the human element from the critical lift stage underneath equipment, by allowing remote control of the lifting device.

TED can travel across any terrain and can safely lift up to 800kg. It has a 360° turntable at the top, which makes lining up ball joints safer, quicker and easier than the conventional methods using slings and chain block.

In addition to making belly plate removal safer, it also makes it significantly more efficient. Safety MITS collected customer data from Thiess, Peabody Energy and Glencore over a one year period and found that by using TED to remove and install belly plates they were able to reduce work time by 73.5% while using one less mechanic.

These savings don’t just apply to belly plates either. TED can also be used for equaliser bars, cutting edges, steer cylinders, load rollers, sound suppression, engine sumps and many other applications.

TED is designed and manufactured in Australia and is built to withstand the harsh environments that heavy equipment works in every day. It is built with total compliance to Australian and New Zealand mining standards (ASNZ 4240) to ensure the highest levels of safety are achieved.

TED comes with a range of attachments, which can be easily installed and removed at a moment’s notice.

These include:

- The Rhino Stand Locator, which allows you to locate stands underneath elevated bulldozers without crawling underneath the suspended load yourself.

- The Cutting Edge tool, which has been designed to assist in the safe removal and installation of cutting edges on bulldozers, graders scrapers and loaders.

- The Load Roller Cradle, which is designed to assist in the easy removal and installation of track roller components on bulldozers, drills and excavators.

- The Tie Rod and Steer Cylinder Cradle, which is designed to assist in the safe removal and installation of steer cylinders and tie rods. The cradle conveniently bolts to the turntable on top of TED allowing it to rotate 360°.

ABOUT SAFETY MITS

Safety MITS specialises in innovative maintenance equipment for the mining and earthmoving industries. From humble beginnings in a shed in Australia, Safety MITS has taken off since its launch 2010 and now services just about every major earth moving and mining company in Australia and internationally. They are currently shipping to the United States, South America and Asia. The latest phase in the company’s expansion has been the launch of Safety MITS USA Inc, based in San Diego California, to provide sales support and servicing for the product in North America.

Drawing on an experienced background in maintenance and coal industries, the safety MITS team developed the world’s first and only remote controlled belly plate jack, TED. Having worked in a range of maintenance tasks in the industry, the Safety MITS team created their business around a culture of eliminating risks and reducing injuries and fatalities by providing innovative safe technology.

All of Safety MITS’ products have been developed in compliance with Australian and New Zealand industry standards, which are some of the strictest in the world. In addition to TED, which comes with a range of additional attachments and upgrades to suit different uses, Safety MITS also provides aluminium work platforms and high density plastic cribbing and chocking blocks.

-205x205.jpg)