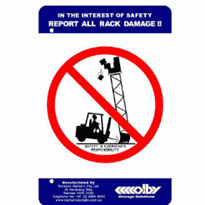

Steel racking is usually used in warehouses and factories to store heavy items such as pallets of goods. Given the amount of weight that the racks are required to support, the steel frames are susceptible to stress which could cause the racks to collapse. It is important for all businesses using steel racks to regularly check the racks for signs of stress to ensure that workers are safe and to comply with legislation.

As with other processes which have been automated by inspection software, the steel rack inspection checklist can be replicated in electronic form, so that inspections can be conducted on a mobile device such as a PDA.

Inspection data is then sent from the field to a central database for secure storage. Certain mobile devices will allow for photographs of problem areas on the racks to be captured and attached to reports. Voice recordings can be made with each inspection and steel racks can be indetified using RFID or barcodes.

Inspection reports are accessible from any desktop computer linked to the database. These reports can be printed or emailed as required. Racking safety inspection software totally eliminates paper-work from the inspection process and allows inspectors to conduct more inspections in shorter amount of time.