Factors such as corrosion, erosion or confusion over which material best suited for the application can degrade a nozzle's performance.

Corrosion and erosion (abrasive wear) are the most common factors that could lead to degradation of a nozzle's performance. Depending on the environmental conditions of the given process, choosing the right material for a nozzle may be as easy as matching an installed material that has proven to successfully weather the conditions. But sometimes there are factors that can lead to confusion about which material is best.

BETE manufactures nozzles in hundreds of different materials and combinations of materials; Spray Nozzle Engineering's and BETE's expertise can help determine the best nozzle material for the job.

Nozzle material selection is influenced by a variety of factors such as temperature, corrosion, erosion, weight and initial vs total costs.

Temperature: Melting or softening of nozzle material establishes maximum temperature limits. However, these limits must be reduced when corrosion, erosion, oxidation or chemical attack are also present in the given application.

Corrosion: Nozzle material performance and reliability varies with exposure to different chemical types and concentrations. It is important to consider both the properties of the environment where the nozzle is installed and the properties of the fluid spraying through the nozzle. Corrosion is material related and caused by chemical attack. There is a very wide range of materials from which nozzles can be made and the proper selection of the nozzle material willl minimise corrosion problems.

Plastics offer superior corrosion resistance at relatively low cost, but can only be used in low-temperature applications. In general, metals can be ranked in the following order of corrosion resistance (from lowest to highest): carbon steel, brass, stainless steel, nickel-based alloys, refractory metals and precious metals. Ceramics have excellent corrosion resistance except in very high pH environments.

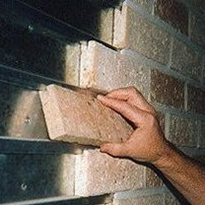

Erosion: Erosion (or abrasive wear) is also material based and can cause the nozzle to wear out prematurely, leading to increased flow and degraded spray formation. This leads to increased process fluid costs and unacceptable process quality. Hardened stainless steel, Cobalt Alloy 6, tungsten carbide and ceramics are commonly used materials in applications where abrasive fluids are sprayed.

Weight: There are situations when minimising structural weight is an important consideration. A nozzle made from a strong, yet lightweight material, such as titanium, can be the perfect solution.

Initial vs Total Cost: Materials can generally be ranked in the following order in terms of cost (from lowest to highest): brass, carbon steel, plastics, stainless steels, cobalt-based alloys, nickel-based alloys, ceramics, refractory metals and precious metals. But, beyond the initial cost of a nozzle, it is extremely important to considet the long-term costs of having a nozzle in a material not suited for the application. Questions to consider are:

- How much do the operating costs increase due to frequent shutdowns for nozzle replacement?

- What is the cost impact to a poor quality product or process due to a spray nozzle that wears out too quickly and performs poorly?

Once the right material is confirmed, BETE and Spray Nozzle Engineering can supply your nozzle, no matter how exotic or routine that material may be.

BETE uses three basic manufacturing processes; injection moulding, CNC machining and investment casting. Injection moulding is used for large quantities of nozzles made from plastics such as PVC, ABS and PVDF. CNC machining is often used for metal alloy and plastic nozzles that have relatively small quantities. Investment casting offers that flexibility to produce complex shapes in common or speciality alloys that provide a unique performance advantage. Multi-component fabricated assemblies in complex designs, with multiple types of materials can also be supplied.

Whether you require confirmation of what's currently in use or a "ground-up" recommendation, BETE and Spray Nozzle Engineering can help you choose the best materials to get the most out of your spray nozzles.