The word 'Kanban', is a Japanese word meaning 'card'. A Kanban 'card' is a visual indicator that a material, ingredient or component used in manufacturing has, or is about to run out.

Just as the sticker telling us there are only two metres left on the roll of plastic kitchen wrap indicates that it is time to buy more plastic wrap, Kanban tags allow manufacturers to be alerted to the imminent depletion of a material, ingredient or component required for production.

As materials are ordered only when there is a need for them, we reduce the storage requirements and wastes associated with obsolete components of dropped product lines, and offer the ability to react, with agility, to changes in demand. This creates a 'Lean' — more efficient and less wasteful — manufacturing process.

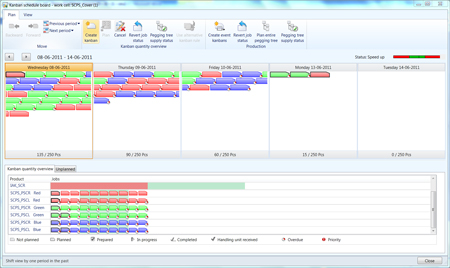

Lean manufacturing allows manufacturers to take advantage of these 'pull-based' principles with the use of the Kanban Schedule — which specifies the material's priority and allows the appropriate timeframe for material's supply so as not to affect production.

Although the basic principles of lean manufacturing and 'Kanban' processes are quite simple to understand, the average manufacturing plant — with many components, ingredients, parts etc. even within a single product line — can have quite extensive and complex requirements which require a streamlined, reliable and efficient solution.

Microsoft Dynamics AX provides extensive capabilities to support lean manufacturing. The Kanban Schedule offers up-to-date information on the availability of materials over time, so the operator always has a clear view of inventory at hand and can anticipate production requirements.

For more information on Lean Manufacturing, Kanban and pull based manufacturing, please click here to download the white paper.