With the discovery of what are known as the ‘rare earth’ magnetic materials in the late 1960’s a magnetic revolution began. Somarium/cobalt compounds were developed, followed in the 1980’s with neodymium-iron-boron compounds which are today produced in large commercial quantities. Their relationship to older ferrite materials is like that of the jumbo jet engine to the engine of a motor cycle. They are many times more powerful, and, harnessed properly, can do much more work.

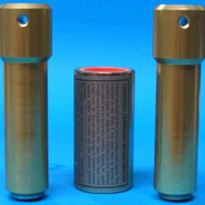

Today, the power of rare earth magnets can be used to lift steel loads of many types. The best magnetic lifter technology focusses all of the magnetic power at the face of the lifting magnet. This technology is used by Tecnomagnete of Italy (represented in Australia by Serpent and Dove® Pty Ltd) and is known and patented as ‘neutral crown’ technology. It ensures that rated capacities can be met even when operating air-gaps such as those created by grit or surface texture of the load, are present. Other features that make MaxX series lifters superior are: monoblock construction, double-magnet circuit comprising magnets in both rotor and stator, ball bearings on the rotor, and, nickel-plating of all steel components for improved surface hardness and corrosion protection.

Perhaps the most significant advantage of the new generation of permanent magnetic lifting magnets is their low weight resulting in excellent power to weight ratios. For example, a magnetic lifter weighing only 6 kilograms can be used to lift a load of 250 kilograms whilst providing a 3:1 safety margin (ie, breakaway at 750 Kgs). What this means in application is that very little crane or hoist capacity is sacrificed to the self-weight of the magnet. A MaxX series lifting magnet rated for 2000 kilograms weighs in at a mere 80 Kgs.

In addition, without the need for electric power, specialised power supplies, cabling and cable reels, a new era has arrived for magnetic lifting and easy steel component handling in many situations.

Some of the most important considerations when using permanent magnetic lifters are the following:

Overall dimensions, including thickness and the estimated weight of the load. Lifting magnets are rated for a particular thickness of steel and must be de-rated for thinner steel. With MaxX series permanent lifting magnets the on/off lever becomes more difficult to turn over if the load is not of appropriate thickness.

Sheet overhang should not exceed certain limits. Sheet sag beyond these limits can cause the load the peel from the magnet face. Serpent and Dove® can provide data indicating safe overhang limits for various steel thicknesses. Where unsafe overhang will result, multiple lifting magnets on an appropriate spreader may be necessary.

Surface condition of the steel to be lifted. Magnetic Lifter capacity ratings assume clean, grit-free, un-painted or un-coated surfaces.

In today’s safety-conscious environment permanent magnetic lifters can frequently provide a low-cost, safe and effective means to improve steel handling and reduce accidents resulting from the use of slings and other unsafe practices.