It not only lubricates the moving parts but also provides sealing and cooling to the airend and directly affects the efficiency of the system as a whole. Selecting the right type of lubricant can lead to a wide range of benefits for the user including higher reliability, reduced maintenance, higher operating temperature range, improved energy ratings and better safety.

Lubricants can be broadly classified as mineral oils or Synthetic oils. Mineral oils are naturally occurring non – vegetable oils. These are refined and derived from crude petroleum oils through the process of distillation.

Mineral Oils

Mineral oils have been in wide use for over 100 years. These replaced vegetable and animal oils as technology improved and the availability of mineral oils became easy. The mineral oils also performed well and were suitable for a wide variety of applications.

While the mineral oils had good performance and suitable characteristics, they also come with some inherent limitations. Chemical properties like quick oxidation reduced the life of the oil. Exposure to high temprature and water contamination can lead to reduce oil life.

Synthetic Oils

A synthetic oil is a chemically engineered man made oil. With an engineered oil, it becomes possible to select the characteristics that are required to suit a particular application. However, it is essential to ensure the high cost of this oil is justified and the user should have either a technical or commercial benefit or both.

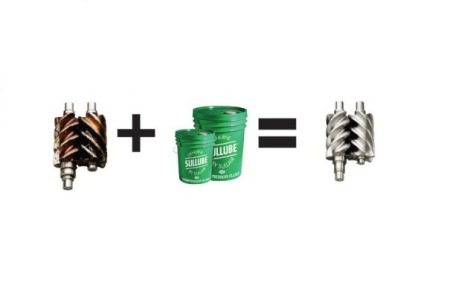

The importance of using the right oil in Compressors - Sullube

In compressors, a lubricant has to handle high temperatures, high pressures, presence of water and is exposed to a lot of dust being passed through the compressed air. Use of a wrong grade of lubricant leads to reduced life of the equipment resulting in breakdowns and loss of valuable production time for the user.

Sullair has been using Sullube™ as our primary lubricant for over ten years in Australia. Sullube™ is a Synthetic polyglycol lubricant that has been designed specifically to combat the issues associated with operating an air compressor under extreme conditions. The following features make Sullube™ an exceptional lubricant for compressed air applications.

- Non-Varnishing Performance – Varnish is the leading cause of air end failure. Sullube does not form varnish.

- Removes Existing Varnish - Performing a flush conversion will remove existing varnish build-up, decreasing energy demand, improving cooling, and extending the life of the air end.

- Cools More Effectively - Sullube™ has higher thermal conductivity which will help the equipment run cooler and allow for easier stabilisation of operating temperature. Compared to a PAO (a different type of synthetic oil), Sullube™ will have a lower operating temperature in extreme conditions due to about 10% higher thermal conductivity.

- Biodegradable Condensate - Since the condensate from Sullube™ is biodegradable, in some cases it can be directly discharged into sanitary sewer systems.

- High Flash Point (263°C, 505°F) - With a high flash point and good cooling ability, Sullube™ promotes safe and reliable operation.

- High Viscosity Index - Sullube™ provides excellent film thickness in all temperatures. Even at 200 °F (105°C) Sullube™ operates efficiently and provides adequate bearing lubrication.

- Very Low Carryover (Less than 1 ppm) - With less than 1 ppm carryover, less fluid is needed for top off.

- Good Compatibility with the Air System - Sullube™ is compatible with the common elastomers found in compressor seals, hoses and solenoids so competitive compressors can be successfully converted to Sullube™.

- Corrosion Protection - Water is always present in rotary compressors in the lubricant.

- Non-Foaming - Foaming increases lubricant carryover.

- Oxidation Inhibited - For longer life.