For all CHP plants, a large number of physical parameters are measured, evaluated and monitored to ensure the longest possible service life. This article offers information regarding which measuring instruments and principles this can be achieved with.

Combined heat and power plants – environment-friendly power generators

In contrast to the traditional boiler or condensing boiler, the CHP plant generates both electricity and heat. Thus, CHP plants make an important contribution to environment-friendly energy generation.

Wide range of applications

The versatile application possibilities, from single or multi-family dwellings, through industrial and commercial, public facilities, up to large district/local heat utilities and also biogas plants, require the use of very different measuring instruments. Key factors are: functionality, quality, long service life, fast availability and services. The price/performance ratio plays a special role in any system – large or small.

The physical measurands

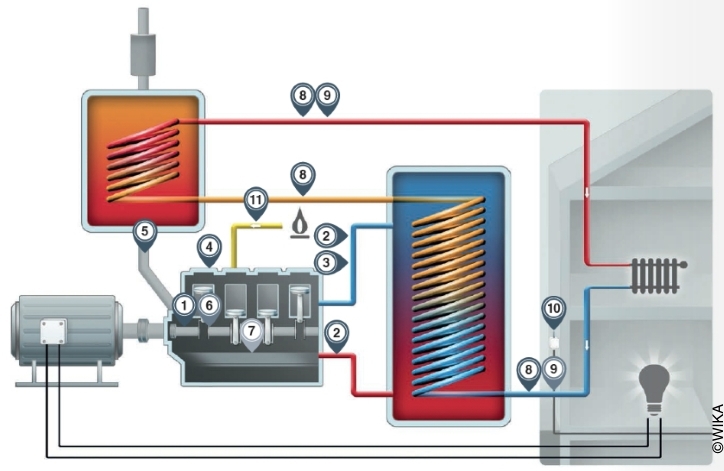

Small nano plants from 1 kWel, micro and mini plants from 2.5 to 15-50 kWel, and also large plants up to 4,500 kWel need the right measuring instruments for high efficiency and environment-friendly energy generation. The measurands pressure, temperature and level are dominant. The energy source must be considered when selecting the instruments. The number of marking points in the schematic illustration of a CHP plant makes it clear: There is much to monitor in order to guarantee the longest possible service life.

Monitoring and control tasks

The measuring instruments used fulfil important monitoring and control tasks and are generally electronic measuring instruments. They also enable remote monitoring.

For measuring the temperature, screw-in, insertion and contact probes are installed, matched to the design and the space available. On the heat exchanger, in the heating and cooling circuits and also for measuring the engine oil temperature, Pt100, Pt1000, KTY and NTC measuring elements are used. With large plants, temperatures on the exhaust pipe and on the cylinder head are monitored using thermocouples. This allows conclusions to be made about the effectivity of the engine.

Pressure switches and pressure sensors are used to control the oil pressure and the pressure in the cooling water circuit. At the same time, they also fulfil a safety function. If there are any deviations between the SET and ACTUAL value, depending on the concept, either a warning signal is triggered or the engine is switched off.

To monitor the oil level, depending on the size of the system, between one and three float switches are installed. Particularly in large engines, the sometimes very strong vibrations pose a challenge for the measurement technology. The use of optoelectronic level switches that tolerate high temperatures and which are not harmed, even by strong shocks, is therefore ideal. The respective level switch monitors the oil level in a reservoir and signals when the oil level drops too low.

Conclusion

The large number of measuring points and the widely differing measuring tasks require close cooperation between the CHP plant manufacturer and the manufacturer of the measurement technology. Therefore, it is worth – both technically and economically – choosing a supplier who offers everything from one source.

Note

WIKA offers a large selection of reliable measuring instruments for pressure, temperature and level. Please contact us for more information.

-205x205.jpg)