Over a long period of time, there has been a problem with tiny metal fragments contaminating meat meal products, a bi-product of meat processing. During the process of turning the offal from slaughter into meat meal, the small drenching capsule remains in the animal's stomach at the time of slaughter.

These are then ground up by the mills and grinders in the facility, causing metal contamination in the meat meal. This can then lead to large product recalls, costly damage to brands and sales and also damage to processing equipment.

A large meat processing facility in Goulburn NSW had these issues and contacted MAGNATTACK™ Global for help. MAGNATTACK™ Global carefully inspected the facility and the source of the issue and subsequently provided a special self-cleaning magnet system that was incorporated into the flow of meat meal.

Much investigation and careful consideration was given due to the nature of the product and its properties, which often make it difficult to treat.

Following the installation of this equipment, metal fragment issues have dramatically reduced and Southern Meats is completely satisfied with the end result.

A spokesman for Southern Meats said: "The system is excellent and I'm happy to tell anyone who has the same issues about it."

As a result, MAGNATTACK™ Global has already designed and manufactured two more large units for Fletcher international meats in Mudgee, NSW, and Albany, Western Australia for the same issue.

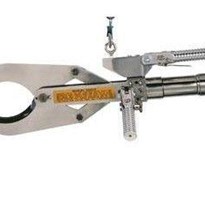

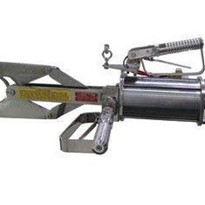

The MAGNATTACK™ Self Cleaning Grate Magnet System that was used is a very versatile machine with the ability to collect weakly magnetic fragments such as work-hardened stainless steel and magnetic stone particles – and can be automatically cleaned both during production and before or after production runs.

Kevin Baker, General Manager at MAGNATTACK™, said: "We have developed a self-cleaning magnet system designed to assist with effective removal of metal fragments generated from ground up drenching capsules, which can cause major damage to extruders and machinery in rendering plants and impose a threat to livestock which ingest metal contaminated meal pellets.

"In a recent incident, meat offal from a major slaughter house in WA contained the drenching capsules which in turn caused the exact above-mentioned problem. The MAG-RAM™ Magnet technology was able to successfully solve the issue and save potentially hundreds of thousands of dollars' worth of plant damage and protect livestock from potential harm," Baker said.

The system can be installed virtually anywhere, including difficult-to-access locations. The self-cleaning magnet system cleans periodically on a timer using either stand-alone controls or PLC controls. Frequency of cleaning parameters can be adjusted according to the level of contamination and product throughput.