The company caters to a wide range of South Korean architectural firms, which use Modelzium's services to build accurate 3D models of buildings and constructions.

The challenge

Traditionally, Modelzium used manual techniques and CNC machines to produce architectural models. However, this process required painful compromises.

"We would often omit some parts that required fine details, such as spheres, oval shapes, or thin parts," Yang Ho Park, CEO at Modelzium, said.

This limitation became more critical as South Korean architectural firms started integrating typical designs in more and more of their work – requiring the modelling of non-geometrical shapes with irregular contours.

In order to keep up with industry trends, Modelzium had to be able to model complex designs with highly accurate details.

Modelzium also realised that relying on manual modelling techniques was not scalable and was limiting its growth.

Looking forward, the company needed to streamline and automate its process if it wanted to expand its modelling business.

The solution

Despite the investment required, which was a significant consideration for the small modelling firm, Modelzium decided to purchase the Objet Eden350 3D Printer.

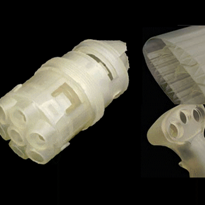

"We were particularly impressed by the fine details and smooth surface finish of the printed models," Yang Ho said.

"Objet's pricing was quite competitive compared to the alternative we examined."

The value

The Objet 3D Printer has brought a substantial production transformation to Modelzium, as it switched overnight from manual to automated modelling.

"The operation of the printer is so easy and convenient that we use it frequently for all jobs - including for parts that can be easily done by hand," Yang Ho said.

"Compared to our previous CNC modelling, where we had to rely on skilled CNC engineers, now all our staff can use the 3D Printer with very little training."

Accordingly, the company estimates it has cut its model production costs by 30-50 per cent.

More importantly, the Objet 3D Printer has allowed Modelzium to stop compromising on model accuracy and detail.

Yang Ho said: "If in the past we used to 'cut corners' and spend a significant amount of time finding ways to handle complex designs, now there is no architectural design we cannot handle – including those with the highest level of detail.

"We recently completed a highly detailed model of a safari zoo, which required modelling realistic topography and animals involving fine details. We would not have been able to win this project without the Objet 3D Printer."

Compared to the previous CNC method, turnaround time for model delivery has been reduced by 30 per cent for standard designs, and by 50 per cent for the more complex atypical designs.

Modelzium can now deliver complete architectural models during the early stages of the design, and follow up with multiple model iterations that can be provided with a quick turnaround.

"When we compete with other firms on getting modelling projects, our new 3D printing abilities definitely provide us with a competitive edge," Yang Ho concluded.