In this case the quality of the packaging is just as important as the productivity and multifunctionality of the actual packaging line. Packaging lines must also satisfy the highest requirements in terms of productivity, flexibility and reliability.

Flexible drive technology guarantees that foodstuffs are packaged quickly, precisely and carefully.

Whether the requirement is to package surimi and sandwiches, finished products or frozen foods, cakes and pastries or even chocolates: the French company Euro Cri, based in Coulommiers, has been developing and building packaging machinery for more than 20 years - from standalone modules through to complete packaging lines. They also upgrade packaging machinery. The emphasis is on packaging machines for end products. And development at the French packaging line manufacturer focuses on the productivity of each individual machine.

Packaged with care

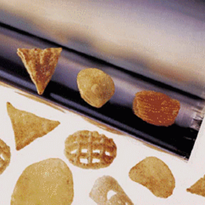

Foodstuffs must be packaged precisely, safely and, above all, carefully. That final factor alone presents a particular challenge for packaging line manufacturers, whose machines need to meet increased standards when packaging delicate foodstuffs. For example, when positioning or spacing products, it is particularly important to avoid them being flattened or becoming damaged during the actual packaging process. What's more, packaging machines for the food industry should also be able to guarantee higher frequency packaging.

The "Dynamic Stocker" accumulator made by the French firm Euro Cri converts an irregular product flow at the output of a production machine into a regular flow, as found when packaging biscuits, surimi or chocolate for example, and that's before the products reach the packaging machine - a horizontal flow-packer. The accumulator gathers the unpackaged products as they arrive and creates a "buffer store", which can be regulated according to the change in the material flow.

The accumulator, which was integrated into an existing packaging line, was developed and built by Euro Cri in close co-operation with Strasbourg-based Pilz France Electronic, the French subsidiary of Pilz GmbH & Co. KG, based in Ostfildern near Stuttgart.

The greatest challenge was to arrange the packaging process so that it was hundred per cent synchronous with the rhythm of the existing horizontal flow-packer. The flow-packer forwards incoming products in an irregular sequence. No pressure may be applied, nor may any friction be created, so it is important that the products have only the slightest of contact and are forwarded immediately - whether individually or in groups.

The development and design therefore demanded an automation solution which was not only capable of controlling complex movements but could also handle various transport speeds simultaneously. The focus was on the movement of a total of six axes: the incoming, connecting and outgoing conveyors, the separators and the axes for synchronisation and the flow-packer. It had to be possible to co-ordinate the axis movements with one hundred per cent accuracy, so that the various speeds at different points of the conveyor could be synchronised precisely and safely regulated.

Euro Cri opted for a Pilz motion control solution (PMC), which enables precise synchronisation of the respective motion processes.

Complete packaging solution

As a supplier of complete automation solutions, Pilz France supported the French packaging line manufacturer from the planning and development stage right through to implementation and commissioning on-site at the customer's premises. The "Dynamic Stocker" has been developed to meet the customer's specific requirements: the engineering process was focused on performance optimisation and the reduction of implementation costs.

The central element of the motion control solution is the controller-based control system PMCprimo 16+, which performs the complex motion and control functions.

Used in conjunction with the servo amplifiers PMCtendo DD and the servo motors PMCtendo AC, the result is a drive solution which can react flexibly to different format specifications and can be used to implement high cycle counts with ease. The PMCtendo AC motors provide particularly good controllability. The absolute position of the motors can be read not just during operation but also after the machine is shut down or after a power failure. Systems with PMCtendo are always modular and expandable as a matter of principle. As a result, users can react flexibly to any product changes. The open hardware and software architecture enables staff to get to grips with the system quickly and easily. In addition to simplifying positioning tasks and storing motion tasks, the PMCtendo DD also provides the power supply and motor drive on the "Dynamic Stocker". Communication between the control system and servo amplifiers is via CANopen.

Packaging process is safely monitored

The packaging process can be monitored and regulated using PMIvisu operator terminals. The motion curves relevant for the cycle are calculated in the simplest way possible: the operator simply enters the set data on the operator terminal - the packaging length and the position of the section to be embossed, etc - and the system automatically calculates the motion profile for runtime. Any adjustments for "new" products are made via the operator terminal, whereby the material flow control system reliably fulfils all requirements regarding the different product types. The display can be used not only to select recipes but also to view precise, clear error messages. The cause of the error always appears first; at the touch of a button the operator then receives specific instructions on how to rectify the error.

Safety-related functions such as emergency stop, emergency off, or safety gate monitoring on the "Dynamic Stocker" are reliably monitored via the compact safety relay PNOZsigma. Non-contact magnetic safety switches PSENmag are used for safety gate monitoring. These meet the very highest hygiene requirements and provide simple protection against defeat in accordance with VDE 0660. The PSENmag safety switch was incorporated into the overall solution to ensure that the packaging process is not interrupted unnecessarily; it is suitable for the very highest hygiene requirements and provides one hundred per cent protection against defeat. It completely excludes the possibility of the switch being operated unintentionally.

The first machines are being used successfully; other projects are already at the planning stage.

"With Pilz we have gained a competent partner in the automation industry. We will continue to work with them in the future to develop leading-edge packaging systems for our customers," says Mathieu Carie, Head of Automation at Euro Cri.