With the launch of the Veo+, Sonatest is also releasing a new software option unique to the Veo+, Phased Array - Curved Surface Correction (CSC).

Using phased array (PAUT) for flaw detection on pipes poses numerous problems, as the contact surface is curved. Not only the outside diameter (OD) causes some difficulties for the interface, the inside diameter (ID) will reflect each beam of the S-Scan at changing angles, as the reflection comes from a convex surface.

The software allows the unit to calculate the beam path using a true representation of the curved part. This allows the unit to take into account a different reflection angle for each beam which ensures a proper coverage of the beams, with a known spatial resolution, totally independent of the curvature of the ID, in turn giving better coverage and optimal beam quantity.

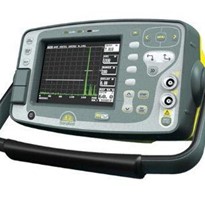

Superior Digital Technology

The VEO+ electronic & software is powered by a new architecture offering superior data throughput and unsurpassed computational capacity to deliver fast and accurate results in the most demanding conditions. It allows inspectors to easily create high resolution volumetric scans and record very precise data sets with exceptional measurement precision.

These performances come from an impressive 32 channel PA beamformer providing exceptional SNR, enhanced digital signal processing and the legendary Sonatest ActiveEdge® pulser technology. Thanks to its Linux® 64-bit operating system and its fast 128GB SSD memory capacity, data file size is not a concern for VEO+. Data compression is yet another feature allowing one to record huge amount of information in more manageable data file size.

Onboard Live 3D Scanplan

The Veo+ embedded modelling tools support multiple probes and scans, enabling quick and efficient set up of inspection plans. Choose from a range of weld geometries, render and visualise probes on the part, at precise locations, representing reality with high fidelity. Then add sound paths, with skips, allowing to assess and ensure proper coverage as planned in the scan plan.

The VEO+ embedded modelling tools are invaluable assets and a reference for the inspection report, communicating inspections results more completely and more clearly, as well as providing precious information to increase users’ level of expertise. This feature makes the VEO+ a choice of excellence for serious NDT schools looking to provide the best academic training to the future inspectors.

Remote Control Solution

Using Sonatest’s UTLink software application, VEO+ can be fully used and controlled remotely, via a simple network connection. As VEO+ now offers WiFi along with its fast GB Ethernet port, the possibilities are practically unlimited. What about getting real-time advice by an expert sitting anywhere in the world? Absolutely!

- Available for Windows 7, 8 and 10

- Easy installation with quick connection procedure

- Very simple user interface (virtual instrument!)

- Instrument auto-detection (works for veo+ & prisma)

Advanced Analysis Software

UT Studio software application, which comes as part of the Veo+ package, is used to manage inspection configurations, perform data analysis and build precise reports. Veo+ data files are easily transferred via a network or a USB data key to the PC.

Then, thanks to a comprehensive, right click / drag and drop user interface, one can create new data views, customize colour palettes, add and modify gates and measurement parameters, generate extended reports and much more. In no time, be able to accomplish amazing things and get the job done.

Rugged

The VEO+ enclosure has also been designed to withstand the toughest of environments and has been successfully tested in the field for 5 years.

-205x205.jpg)