The installation and integration of the best available equipment is being taking care of by the largest European material handling integrator so that this popular Turkish fashion brand can continue growing with no worries about its supply chain.

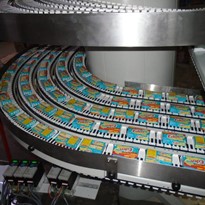

The brand new building includes some challenging elevation requirements and so AmbaFlex was asked to find some innovative solutions for them. As it was very important that there were no bottlenecks, spiral conveyors were obviously the way to go. And only AmbaFlex could fulfill the demanding specifications effectively thanks to their popular SpiralVeyor®. With over 10,000 units already in operation and serving some of the most demanding applications, the SpiralVeyor® is one of the most proven links in this new warehouse’s product flow.

The elevation height requirement meant that AmbaFlex was the only realistic candidate that could deliver an effective solution. The tallest spiral conveyor measures over 22 meters in height, and all spirals add up to a total of 165 meters. Although AmbaFlex has supplied higher spiral configurations before, the total elevation is a record in spiral conveyor world. The AmbaFlex SpiralVeyor® with Triple-E Technology (offering the lowest rolling friction) is an ideal and effective solution. And for such heavy applications, the Triple-E technology delivers an energy saving of up to 45% compared to typical solutions.

Of the 18 units supplied, some simply elevate items as part of a multi-level merging solution. AmbaFlex invented multi-level merging over a decade ago and has installed many units as picking modules since then. The concept is simple, multiple stacked picking levels merge cases with picked items into a continuously moving spiral conveyor. A clever invention that means a very compact layout for the picking module.

A key advantage of the SpiralVeyor® is the rigid welded steel space frame that enables it to be assembled and stacked up to great heights. And in this project, the space frame was extremely useful as access to the final location was tricky due to the enormous length of the spiral. For that reason, the pretested and preassembled spirals were fitted with flanges in the space frame so that each one could be added separately and stacked on-site with just a few bolts.

One more proof of AmbaFlex’s leading position in Spiral Conveyor Solutions!