Unsealed Road Material Loss Case Study 2017

We're very pleased to share the latest results on research conducted in 2017 to demonstrate the benefit of PolyCom Stabilising Aid in unsealed road maintenance. The results of this study prove that naturally occuring materials are suitable for making unsealed roads of high quality and performance whilst reducing the need for importation of expensive gravel and or manufactured quarry materials.

The PolyCom Stabilising Aid Material loss Case Study

The data below has been compiled from field reports during 2017 in VIC and NSW. The results show material loss comparisons from 14 different unsealed roads of different material types and locations. All data was verified to ensure accuracy. Due to variables such as weather, material, location and traffic loading. This study represents strong proof of the benefits of PolyCom in the field in real world conditions.

What is a ravel test?

A ravel test consists of placing a 1m2 frame on the road, within the wheel path section and sweeping up all the loose material available within 1m2. The material is then bagged, weighed and recorded. This process is repeated for treated and untreated sections of road up to 4 times per km to aid in providing quality data. Ravel test methodology here.

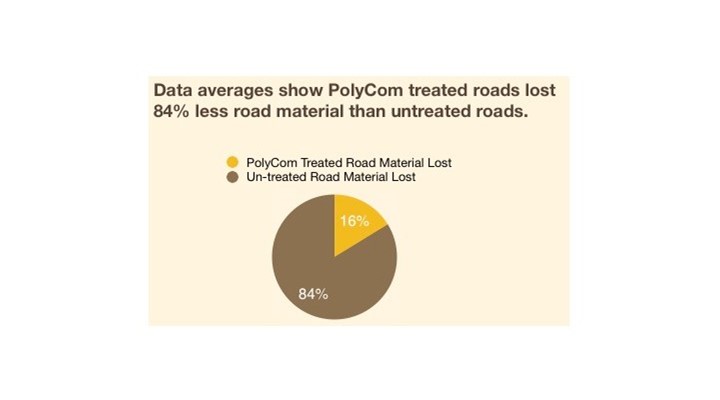

Results of PolyCom Treated vs Un-treated:

Sandy clay - treated 93.7% less material loss

Pit gravel or ridge gravel non crushed - treated 74.7% less material loss

Clay with some gravel (ready for re-sheet) - treated 94.2% less material loss

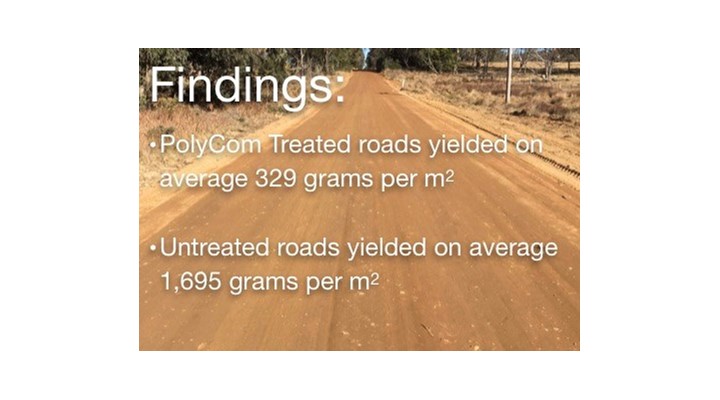

Overall findings:

a) PolyCom Treated roads yielded on average 329 grams per m2

b) Untreated roads yielded on average 1,695 grams per m2

Conclusion:

The results confirm that PolyCom is very effective in lowering maintenance costs and making for a safer more sustainable unsealed road network that requires 4 to 6 times less maintenance grading.

Benefits of PolyCom:

- Financially sustainable

- Environmentally compliant

- Reduced purchase of re sheet materials

- Less trucking by using in-situ material

- Considerable reduction in fuel use

- OHS compliant

- Less repeat work

- Reduced sediment run off from roads

- Reduces mud and dust

- Use existing crew and machinery

- Treated roads are less slippery when wet

For more information download the latest PolyCom Stabilising Aid Tech document from the American Society of Civil Engineers.