Unimax is an Auckland, New Zealand-based label printer specialising in the printing of agriculture, transportation, health and food & beverage labels. With more than 30 years’ experience, Unimax is committed to offering the best value labels. The company aims to reuse or recycle the majority of its physical waste, reduce energy consumption, improve workplace efficiency and safety, and help customers lower their environmental impact.

GROWING THE BUSINESS WITH DIGITAL PRINTING

To support the growth and competitiveness of its business into the future, Unimax was looking to offer more variety in the printing options available to customers. Unimax made the decision to invest in a new digital printing solution.

“We were looking for a digital printing press that offered the highest quality print product, consistency and was the most cost effective,” said Dinesh Kumar, Director at Unimax. “After weighing up the available options, we made the decision that the Screen L350UV stood out as the best solution.”

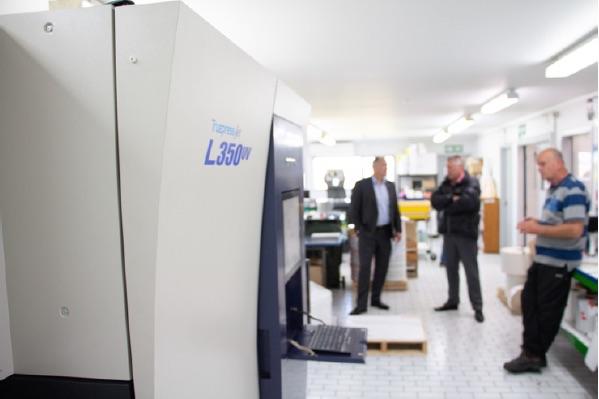

Jet Technologies was brought in to consult on the Screen Truepress Jet L350UV with the assistance of Screen GP Australia and installation by Fujifilm NZ with after sales support. The L350UV offers a modern addition to the Unimax business, that was previously only printed conventionally. “By now being able to offer its clients both conventional and digital printing, Unimax is positioned as a fully-rounded label print house,” said Jack Malki, Director, Jet Technologies. “This allows them to offer a variety of options to customers.”

THE BENEFITS OF THE L350UV

The Screen L350 was an attractive option for Unimax due to the fact that its high speeds make it a very cost-effective option. Additionally, it delivers a higher uptime of 94 per cent compared to other printers, meaning more throughput and less bottlenecks.

Digital printing opens up more colour options, including white ink, and the colour is more vibrant. The L350 also ensures that colour consistency is assured on every job. Label durability is also another benefit of the printer, with a longevity of 12 months minimum.

“We needed a press that was capable of high-quality labels that wouldn’t scuff, fade or scratch,” Dinesh explained. “With the L350 we can also print on a wide range of substrates, including textured and silver, which avoids the need for top coating finishes such as foils. Being digital, the Screen L350 allows for variable data printing, while keeping set-up times low. It also opens the door to much more customisable labels to meet the needs and preferences of customers.”

THE RESULTS FOR UNIMAX

Investing in bringing digital printing in house, rather than having to outsource has made Unimax a more competitive and versatile label printing business. It has made a big impact on the productivity of Unimax’s label printing, which has enabled the company to increase capacity and take on more customers.

“The L350 is a very fast printer and on average we’re printing at 50 metres per minute. With the print jobs we’ve been able to move over from conventional printing & we have halved the time required,” Dinesh explained. “We’re also now able to offer customers a solution if they have urgent print jobs, as with the L350 we can do these in a day.”