Simplifying Thermal Bridging

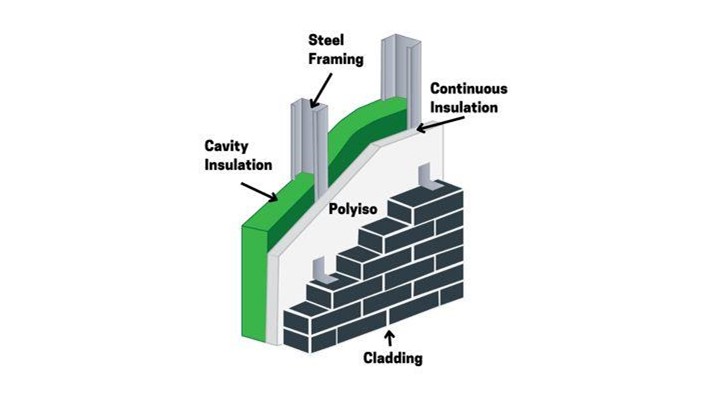

Thermal bridging refers to an event where parts of a building’s envelope, such as walls, floors, or roofs conduct heat more easily than the surrounding materials creating a path for heat to flow from warmer to colder areas. Thermal bridging occurs on some level in all construction when using steel or wood framing. Although steel is more susceptible to thermal bridging. When addressed properly structures built from cold formed steel can be some of the most energy efficient. If thermal bridging is not corrected it can lead to increased energy costs, the potential for mold in wall cavities and in extreme cases structural failure. By confronting the issue and taking action these issues can be avoided.

Easy Solution: Thermal Break

The solution is quite straightforward. It involves forming a thermal break on the building’s exterior to separate the warm and cold air. Additionally, the use of a proper vapor barrier on the interior will stop moisture from entering the wall cavity while allowing it to escape. Generating a thermal break on the exterior wall can be achieved by using continuous insulation. The typical materials used include expanded polystyrene (EPS), extruded polystyrene (XPS), and graphite polystyrene (GPS). Continuous insulation in conjunction with the cavity insulation will need to meet the required effective R-Value as dictated by the local building code. The thermal break can also be achieved by using less conductive materials directly attached to the cold formed steel (CFS) framing on the exterior. Fiber glass z-purlins are one example of such a material. It is important that the material of choice used to create the break shows a fire-resistance rating that is applicable to the local building code, to lessen the risk of a fire.

In conclusion, the thermal bridge needs to be rectified and can be done in multiple ways. Exterior continuous insulation is the most common choice for creating a thermal break. Building designs must be mindful of how they are achieved without creating gaps in the thermal break. Proper thermal breaks, adequate wall cavity insulation and an interior vapor barrier can maximize energy efficiency and maintain a high level of air quality inside.

-205x205.jpg)