Background

COVID-19 has placed enormous strain on healthcare systems around the world, the UAE included. When the world was hit with the COVID-19 pandemic early in 2020, there were many concerns regarding the surging number of infections, and whether the healthcare facilities are equipped to adapt to the high hospitalization rate. This includes hospital beds, staff, medical equipment, rooms, etc.

The UAE has been extremely active in its response to the pandemic. Many providers encouraged innovation, backed by excellent federal and local government handling of the crisis. As the National Disinfection Programme was swiftly implemented across the country, field hospitals were set up in record time, and the high-profile vaccine rollout marks the UAE apart as one of the country's leading the world in vaccine administration.

FRAMECAD technology and fast construction projects always work hand in hand. The fast design, quick assembly, and low-weight components accelerate the construction end-to-end process. This was much needed in field hospitals, where speed is crucial to provide additional healthcare facilities for the public. FRAMECAD’s customers completed several field hospitals around the country, one of which is Sheikh Mohamed Bin Zayed field hospital in Fujairah, funded by the government of Abu Dhabi.

The project was awarded to Purple Exhibitions, where the 4100m2 was completed in a record 30-days in July 2021. This included the cold formed steel structure, cladding, roofing, electrical and mechanical installation and all the medical equipment. Purple Exhibitions thought no further than FRAMECAD’s cold formed steel construction and contracted one of FRAMECAD’s key customers in the UAE, Speedhouse Group, for the structural design, fabrication, and supply of all steel elements.

The End-to-End Process

With a short lead time of 30 days, speed was critical. Transportation of construction workers needed to adhere to the social distancing requirements imposed by the municipality which indeed imposed additional construction challenges.

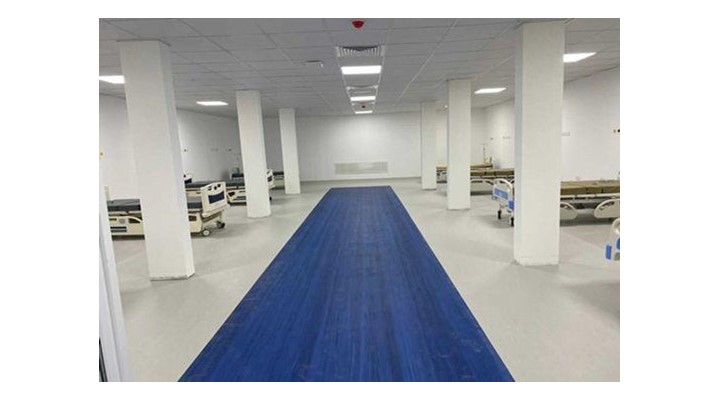

The 90-tonne steel project of 4100m2 floor area consists of 216 beds, including 56 ICU beds and 160 beds for moderate and minor cases, as well as a patient affairs office and a Covid testing lab.

Speedhouse Group engineers and detailers began the design process immediately which took a total of one day to complete, utilizing FRAMECAD® Structure for the construction details, structural design, BOQ reports, and engineering reports. The files were then exported to FRAMECAD® Detailer for the full fabrication of the frames.

Following confirmation of the final design and detailing, it was time for manufacturing. The team at Speedhouse Group began producing the frames using the directly exported production files from FRAMECAD Detailer into FRAMECAD Factory 2.

With a production speed of over 600m/hr, production of the frames took just over 5 days (two shifts per day), using two of FRAMECAD’s F325iT systems. The profiles used were 63mm for bathroom walls and 89mm for all other walls and the roof. All the assembled frames were transported directly to the site in Fujairah by day 9. All steel coils were high strength G550 MPa.

After the erection of the frames, Purple Exhibitions started the cladding process, utilizing fiber cement boards externally, glass wool insulation, gypsum boards internally, and sandwich panels for the roof.

Given the stringent thermal, fire and sound requirements by the municipality, the selection of building materials for the project was all made easy using FRAMECAD’s subassemblies manual which references the fire and sound test certificates of FRAMECAD’s wall panel, floor, and roof systems.

By the end of day 14, all civil works were completed using the 45-man workforce. This gave Purple Exhibitions a comfortable 2 weeks to complete the MEP works, thanks to the fast design and production of the FRAMECAD’s technology. The hospital was completed in a record 30-days. The hospital is centrally air-conditioned, using unique systems of pressurized-negative air to enhance the quality of air and ventilation and to distribute the air inside wards only to prevent spreading the virus to other areas of the hospital through ventilation systems.

Mr Bilal Mousa, Construction Director at Purple Exhibitions stated: “the project 30-day deadline wouldn’t have been possible without FRAMECAD’s cold formed steel technology. The frames were designed, assembled, transported to site in a record 9 days, earlier than we had anticipated. The only challenge we faced was splicing the 40m trusses on site in which 2 cranes were used simultaneously. We initially thought that this was going to cause major delays, but the fabrication details in FRAMECAD Structure was clear and made the assembly of the splice much easier. We faced challenges with the hot weather and the COVID restrictions. Overall, it has been a brilliant CFS project, and the hospital was delivered even ahead of schedule. We look forward to having our own FRAMECAD F325iT system so that we can produce our frames internally”.

-160x160-state_article-rel-cat.png)

-205x205.jpg)