This new high-capacity packaging system has helped to considerably improve the securing of pallet loads.

Vinnolit produces and markets a broad range of PVC products that are suitable for all kinds of PVC applications in the building and construction sector, in the automotive industry or in the medical sector. It is also one of the leading manufacturers and suppliers of intermediates such as caustic soda vinyl chloride and tin tetrachloride, which are required in the chemical industry, as well as in other industries.

"Some of our PVC powder is filled into paper bags that are then stacked on pallets," explains Reinhard Birnkammer, head of SCM Polymer.

"But due to the different bulk densities of the individual products, the finished stacks are of different heights." Previously, the company used a shrink wrapping system, which is now outdated and no longer meets the quality standards.

"Not only did it take 20 minutes to change the film roll, but the choice of film was also very limited," says Birnkammer. Moreover, they switched to the BEUMER stretch hood because of increasingly high standards for the stability of the palletised stacks and the fact that the paper bags are equipped with valves that sometimes ripped holes in the films.

Stretching instead of shrinking

"In order to package the stacks more efficiently, we knew that we needed a new packaging system," says Reinhard Birnkammer.

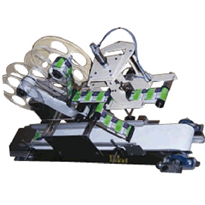

"BEUMER was our first choice - after all, we had already used the BEUMER stretch hood technology at several Vinnolit sites successfully before. Soon we were satisfied that the BEUMER stretch hood S was the right solution for this application."

The machine concept of this high-capacity packaging system is flexible and can be adjusted individually to different project situations and applications. "One of the winning arguments for us was the fact that the machine control can automatically detect different stacking heights.

We can also choose from a wide range of films, and the PE stretch hood films that are used have a very high breaking strength and piercing resistance," explains Reinhard Birnkammer. The required elongation values and the biaxial tension forces can be optimally adapted to each product and to the respective operating conditions.

Before choosing the BEUMER stretch hood S, the head of SCM Polymer and some of his staff members came to visit the BEUMER testing facility in Beckum. "We conducted several test runs and tried different film types, in order to test the securing of loads on pallet stacks of different heights."

These prior tests enabled the company to put the system into operation in Gendorf after only a few days - instead of several weeks. "We could exchange the systems without any problems and fit the new system into the existing conveying technology," says Birnkammer.

Efficient packaging

In the packaging line, first the PVC powder is conveyed from the silo into the primary hopper and from there it is charged into the bagging system. From there it is filled fully automatically into paper bags that are then sealed. The bags are transported by conveyor to the weighing unit. Roller conveyors transport the bags on a belt conveyor with a bag flattening unit, then they are transported from the palletiser to the stack press.

"Here the air is pressed out of the bags," says Birnkammer while pointing at the station.

"This is how they get their flat shape and why the finished stack will be much more stable."

The entire stack is then automatically conveyed to the downstream BEUMER stretch hood packaging system on roller conveyors. "Our new system is a cost-effective and environmentally sustainable approach to pallet packaging, with low specific energy and compressed-air consumption, as well as compatibility with recyclable packaging films," explains Birnkammer.

Furthermore this system does not require complex, energy and cost-intensive hydraulic systems, as is often the case with comparable packaging systems.

While Birnkammer is speaking, the BEUMER stretch hood is positioning a stretch film hood over the stacked pallet. "An ultrasonic sensor is determining the exact height of the load unit," Birnkammer explains. "The film hood is sealed and cut at the specific length required for the stacking height."

The stack can have a height of up to 2,200 millimetres. The film hood is stretched horizontally after the sealing and elongation process. The degree of stretch is defined by the stack dimensions, film elasticity and film gusset dimensions and by the required stability of the stack. Motorised rollers - used first to crimp the film - move into position for transferring the film, while gripping the film throughout this movement. The hood is stretched over the entire pallet load and under the pallet - where the rollers and the crimping bows release the film, in a coordinated action, to form the understretch.

"The understretch secures the load on the pallet in a vertical direction," says Mr Birnkammer. The film's properties are such that the film stretches over the entire pallet load and then snaps back into place at the understretch, thus providing a better seal.

"This system offers a much better securing of loads," emphasises Birnkammer.

"Unstable loads have a much higher risk of tilting."

The palletised bag stack is now protected on five sides against humidity, dust and dirt. The smooth film surface ensures high visibility of the packaged goods. Fork-lift trucks transport the packaged bag stacks to the block storage.

In Beckum, Birnkammer learned that stretch hooding has additional advantages compared to shrink hooding. "Not only does it ensure a better securing of loads and offers a higher flexibility, but it also helps us to reduce film consumption by 30 per cent and maintenance costs by 40 per cent."

"Our cooperation with BEUMER has always been very successful" Birnkammer sums up their partnership.

-205x205.jpg)