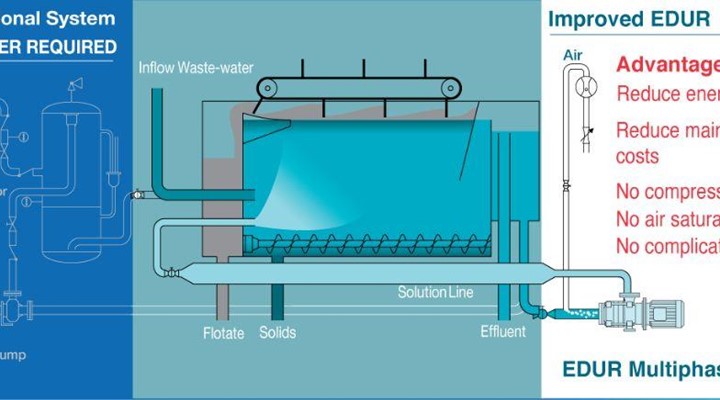

Food process companies can improve the reliability of their DAF system and reduce maintenance costs by throwing out their compressor and air saturation [pressure] vessel and replacing their existing pump with an EDUR “multiphase” pump, according to Australian distributors, Hydro Innovations.

The EDUR “multiphase” pump is unique in that it is capable of pumping an air/water mixture, so installing this pump enables DAF system owners to disconnect their compressor [to free it up to use elsewhere, or work it less and save on maintenance costs]. They also don’t need the on-going maintenance and re-certification for the air saturation pressure vessel. With the pressure vessel, they can remove or bypass it, or they can incorporate it into the new system. If they chose to incorporate it, it just becomes part of the pipe system and will not be a pressure vessel requiring certification.

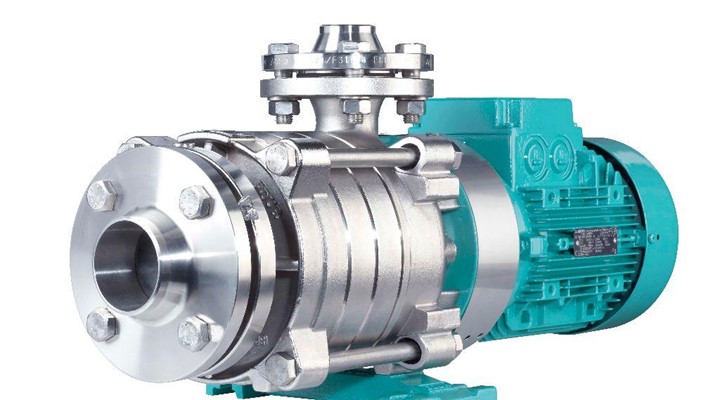

The heart of the new system is the EDUR multiphase pump. The set-up is simple. It is set up with a throttle valve and an “air snorkel” on the suction side of the pump, and a solution line [or re-use the existing air saturation vessel] and throttle valve on the discharge. The pump draws water from the “clean” side of the DAF tank, and with the negative pressure created by partially closing the suction throttle valve, also draws atmospheric air into the pump. The pump shears and mixes the air with the water and discharges it [under pressure created by the discharge throttle valve] through the discharge solution line. The pressure created and the time spent in the solution line “forces” the air into solution.

When the air/water solution reaches the lower pressure in the DAF tank, the air comes out of solution to form tiny micro bubbles [30-70 micron]. The micro bubbles attach to fat, oil and grease [FOG] particles and floats them to the surface of the DAF tank. A FOG blanket is formed and mechanically scraped away [as with conventional systems].

Food process companies can improve the reliability of their DAF system and reduce maintenance costs by throwing out their compressor and air saturation [pressure] vessel and replacing their existing pump with an EDUR “multiphase” pump, according to Australian distributors, Hydro Innovations.

The EDUR “multiphase” pump is unique in that it is capable of pumping an air/water mixture, so installing this pump enables DAF system owners to disconnect their compressor [to free it up to use elsewhere, or work it less and save on maintenance costs]. They also don’t need the on-going maintenance and re-certification for the air saturation pressure vessel. With the pressure vessel, they can remove or bypass it, or they can incorporate it into the new system. If they chose to incorporate it, it just becomes part of the pipe system and will not be a pressure vessel requiring certification.

The heart of the new system is the EDUR multiphase pump. The set-up is simple. It is set up with a throttle valve and an “air snorkel” on the suction side of the pump, and a solution line [or re-use the existing air saturation vessel] and throttle valve on the discharge. The pump draws water from the “clean” side of the DAF tank, and with the negative pressure created by partially closing the suction throttle valve, also draws atmospheric air into the pump. The pump shears and mixes the air with the water and discharges it [under pressure created by the discharge throttle valve] through the discharge solution line. The pressure created and the time spent in the solution line “forces” the air into solution.

When the air/water solution reaches the lower pressure in the DAF tank, the air comes out of solution to form tiny micro bubbles [30-70 micron]. The micro bubbles attach to fat, oil and grease [FOG] particles and floats them to the surface of the DAF tank. A FOG blanket is formed and mechanically scraped away [as with conventional systems].

The major benefits of changing to an EDUR system are the simplicity of a “set and forget” arrangement, and the on-going maintenance cost savings. No more compressor needed means lower maintenance on the compressor. The removal of the pressure vessel means a reduction in maintenance costs and elimination of the need for yearly certification of the pressure vessel. The removal of the pressure vessel also improves WHS around the system.

More information on the EDUR pump/system may be obtained from Hydro Innovations website https://www.hydroinnovations.com.au/pump-applications/edur-pbu/.

-160x160-state_article-rel-cat.png)