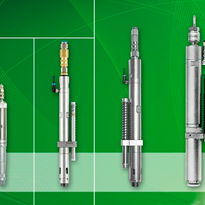

The pneumatic driven NANOMAT is already available as a handheld screwdriver or in spindle form for stationary applications.

DEPRAG's innovative NANOMAT pneumatic screwdriver achieves its highly accurate torque control through the proven principle of the DEPRAG mechanical separation and shut-off clutch.

This enables torque repeatability lower than ±3% and this is sustained for millions of cycles. Under suitable environmental conditions DEPRAG pneumatic screwdrivers with shut-off clutch achieve a Cmk-value of 1.67 with ±10% tolerance in regard to 6 Sigma and in accordance with ISO 5396.

A Cmk-value of 1.67 means a fault rate of just 0.6 per million screwdriving cycles. With minimal time and effort the torque setting can be adjusted on the pneumatic screwdriver without the requirement of a specific tool.

Further advantages have been added by the DEPRAG engineers to their NANOMAT.

"For miniature-assemblies DEPRAG has designed the NANOMAT spindle (automation) screwdriver with a diameter of only 12 mm enabling the smallest centre-to-centre screwdriver spacing for stationary applications," Jürgen Hierold said.

Of course, the NANOMAT also incorporates the proven DEPRAG guide bolt system which regulates the optimal screw end-load pressure by means of engineered spring force.

For manual screwdriving processes the ergonomic shape of the grip ensures tactile and precise control of the screwdriver. A tube built into the screwdriver housing allows integrated vacuum service for picking and control of small screws or fasteners – there are no vacuum hoses cluttering the screwdriver grip.

These features give a clear competitive edge to DEPRAG's screwdriving technology.

The integrated quick-change chuck guarantees an easy and fast change of the screwdriver bit without having to use tools. The NANOMAT is able to accept standard bits, A3-drive type, in accordance with DIN 3126.

The new NANOMAT represents a new product family in a proven DEPRAG screwdriver program. The manufacturer expects that the NANOMAT will take its place among the well known MINIMAT and MICROMAT pneumatic and EC-screwdriver series reputed worldwide.

The entry of NANOMAT into the world of miniature-assemblies, however, is not yet to the satisfaction of the manufacturer.

"As a provider of 'complete solutions' our core requirements in the mini-assembly area are fulfilled; of course, all peripheral instruments such as automatic screw feeding, accurate torque measuring devices, robust and reliable guided tool support stands for manual assembly go along with the NANOMAT screwdriver," Hierold said.

With the development and introduction of the NANOMAT screwdriver DEPRAG SCHULZ GMBH u. CO. once again justifies its ranking as a market leader in low torque screwdriving technology.

The full service provider with 600 employees in more than 50 countries is committed not only to screwdriving technology but also to the concepts and equipment for modern manual workplaces, semi- and full automatic assembly systems as well as to the production of high-quality pneumatic air motors and air tools.

The company is situated in Amberg, Bavaria.

-160x160-state_article-rel-cat.png)