What seemed trivial at certain times, now seems crucial with a global health pandemic still raging on. What is important is that businesses and organisations are able control their OHS in the workplace to the best of their abilities, not only in a responsive manner but a preventative one too. This means adequate inception methods to catch things way before the issues become problems, and inaction turns into consequences. Leading businesses and organisations across several industry sectors and fields are now turning to paperless inspection solutions to manage their OHS inspections. This not only gives them the best platform to launch their OHS within the workplace, but the digital nature keeps them up to date with the latest regulations, and up to date with the ways of working in the 21st century.

Forward thinking organisations and businesses have always been rewarded for changing early to impending changes in the operating environment. Those that challenge the status quo gain the first mover advantage and can showcase genuine leadership in the industry. For safety inspections, many businesses and organisations saw the benefits of having their OHS on a digital platform. Managed by mobile devise in the form of tablets and smartphones OHS inspection means that there are several inspections that can feed into an OHS inspection ecosystem. It means that there are several data points to be measured, which through the various devices and inspection methods, can be kept track of in a better way than with ‘regular’ inspection methods. New features such as photo evidence or using QR codes or RFID for information storage and retrieval improve the speed and accuracy of the OHS inspection data itself.

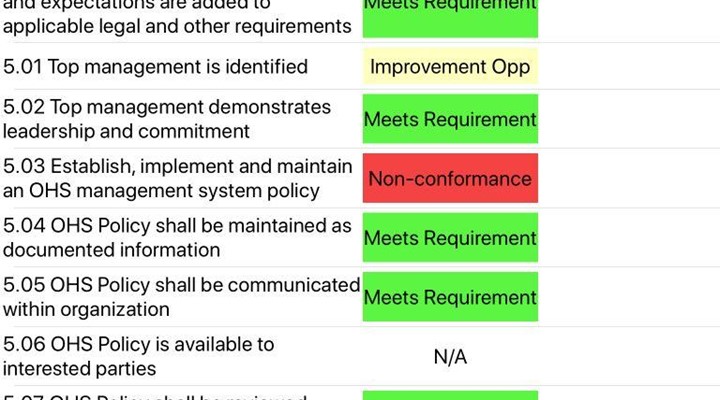

One feature of digital OHS inspection that sometimes gets underreported is the ease of management of the data. OHS inspection is designed to highlight flaws in the system, raise issues that need to be dealt with, but crucially ensure the safety of the workforce and working environment. When problems do occur, the data on digital OHS platforms can be shown across all the inspection systems and automatically trigger notifications to relevant parties. This could be a spillage in aisle 14 that needs to be cleaned which will reroute all staff to avoid said aisle. Small changes in the information sharing across a business or organisation can often have much larger consequences. Similarly, it may be that a particular department carries out OHS inspections to demonstrate compliance or adherence to regulations such as ISO 45005 (Occupational health and safety management — General guidelines for safe working during the COVID-19 pandemic). By undertaking inspection checklists that have been designed specifically in accordance with such a regulation, it becomes a much more simplified process of creating an audit trail.

For OHS managers digital OHS platforms are a welcome tool to utilise in the name of safety. Not only is there the knowledge that it represents the best inspection process and tool that is available for use, but there are several tailoring or customisation opportunities. Besides the trigger notification and automatic email alert mentioned above, there can be automatically suggested corrective actions. Going back to the incident in aisle 14, a user that reports the issue can get a corrective action that either solves the issue straight away, or remedies the state to the best possible temporary outcome. This can give management a great peace of mind in knowing that OHS inspectors or general staff that flag incidents not only let everyone else know of the issue, but have the knowledge available to know exactly what to do until reinforcements arrive.

Revolutionising OHS inspection doesn’t have to be a tough and lengthy process, with digital it can be neither. Whether you work in an agricultural, oil and gas or mining organisation, OHS remains a fundamental aspect of your workplace.

To learn more about ISO 45005 (Occupational health and safety management — General guidelines for safe working during the COVID-19 pandemic), please visit: www.iso.org/standard/64286.html

-160x160-state_article-rel-cat.png)