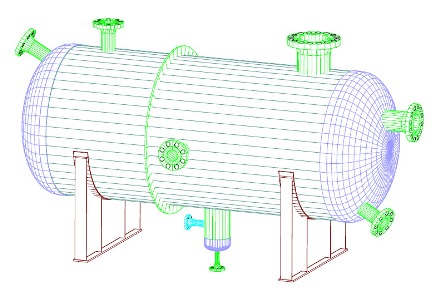

This is so that pressure vessel designs can be registered with the relevant statutory authority prior to the vessel being put into service.

- We can verify your pressure vessel design to the relevant International Standard.

- We can submit on your behalf to any relevant authority in Australia for registration.

- We can help in the process of getting your vessel put into service and meeting the legal requirements.

- Our verifiers are experienced and fully qualified engineers.

Our verifiers are fully qualified professional engineers, members of the Institution of Engineers Australia and Registered Professional Engineers of Queensland (RPEQ). Sherwood Design & Engineering is a Quality Assured company and this, combined with the qualifications of our verifiers, allows us to sign off and submit for pressure vessel design registration in any State of Australia.

Pressure vessel design verifiers at Sherwood Design & Engineering have experience in verification to not only the Australian Standards AS1210 and AS1228, but also the US codes ASME VIII and ASME I, as well as European Standards.

Our verifiers have experience in dealing with every registration body throughout Australia (WorkCover, WorkSafe etc) and can advise you of the registration process. The first step in the process is to determine the Hazard Level of your vessel to AS4343, and based on this Hazard Level, we can advise if registration of the design of the pressure vessel with the relevant authority is required.

If verification and registration of the design is required, we can advise and assist with each step of the process. Once the design has been registered and a registration number has been issued for your vessel by the relevant authority, each vessel made to that design will require Item Registration. We work with a number of Pressure Vessel Inspectors who we can recommend for assistance in the final stage of the process of putting a pressure vessel into service, including pressure vessel inspection and signing off for item registration with the relevant authority.

Pressure equipment design verification is the process where the design is compared to the design requirements of the relevant international standard for the stated design and operating conditions. This is to assure that the design is compliant and that the equipment has sufficient structural integrity to meet the minimum requirements of the relevant standard for in-service conditions. Design verification is not concerned with functionality but is concerned with the equipment safety.