Short Pitch RFID eNcoding Technology, or SPRiNT, offers the first real low-cost solution. SPRiNT enables printing and encoding directly on to the tag inlay. This allows up to a 50 percent reduction in associated costs which will eventually result in item level RFID tagging -

previously deemed price-prohibitive, whilst also enabling use within work processes.

RFID tag inlay manufacturers traditionally supply inlays to label converters to produce ‘Smart Labels’. Known as ‘Wet Web’ media, these inlays are adhesive-backed and the pitch heights between tags is typically very low (approx 20mm). Only SPRiNT™ enabled Toshiba printers can accurately encode directly on to these inlays at such low heights.

So, where little or no printing is required, SPRiNT saves the additional costs of encapsulating an inlay into a ‘Smart Label’, providing a truly low-cost RFID ‘label’ solution.

Feature-rich Toshiba RFID-enabled printers along with quality assured RFID media and branded ribbons will ensure your RFID application is effective, reliable and returns true time and cost savings for your business.

Printer Technology

There are a number of advantages in using Toshiba RFID-enabled printers:

Preventing Tag IC (Integrated Circuit) Damage - the B-SX printer range has patented ‘head-up’ technology where the printhead can be raised as the tag passes, protecting the sensitive and expensive tag IC, resulting in fewer potential tag failures and prolonging the life of the printhead.

Dual Platen Rollers - two drive rollers prevent media slipping or skewing and assist accurate forward or back-feeding to enable reliable tag read/writes.

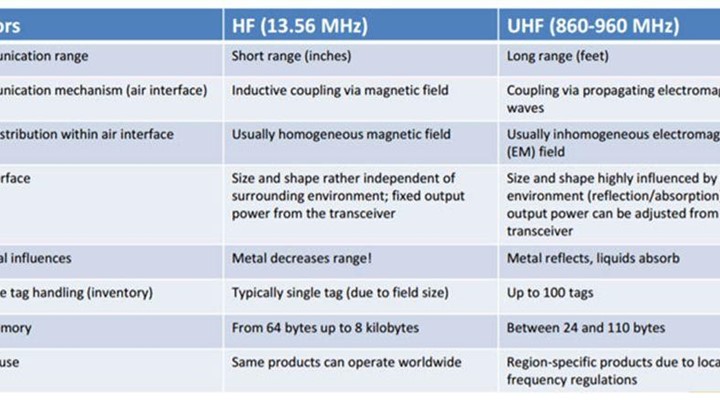

Comprehensive Tag Support – interchangeable, retrofit HF and UHF modules available.

Future-proofing - a modular open architecture policy means that new and unsupported tag types may be supported by simply installing compatible read/write modules.

Fully Integrated - the antennas and read/write modules are fully integrated in the printer preventing potential damage associated with external plug-in options.

Easy Encoding Options - RFID read/write commands have been added to the printer’s powerful, easy to use command language. Label design software and drivers also support RFID encoding.

Encoding Verification - all tag encoding is verified prior to printing, if the verification fails the label will be scored out.

RFID Analysis Tool - determines the tag ‘sweet-spot’ for ideal read/write positioning.

Supply

Supported tag inlays, in a range of sizes and antenna designs, include:

| HF | ISO 15693 I-Code Tag-It TAGSYS (C210, C220, C240) |

| UHF | EPC Class 1 ISO 18000-6b ISO 18000-6c/EPC Class 1 GEN 2 |

SPRiNT Inlays

Quality tag inlays for use with SPRiNT™ (can also be used for label conversion).

Converted tags or Smart Labels, two levels of supply:

Premium (checked & marked)

- Any defective tag inlays are identified and marked on supply roll

- Toshiba printer scores out any defective tags at the print/encoding stage

- Premium Plus (checked & replaced)

- Defective tag inlays are identified, removed and replaced with fully functional units

- High volume or mission-critical applications where 100% supply quality is required

Quality Control

The Smart Label converting process includes integrated high speed, in-line quality control mechanisms and offline quality checks. These testing procedures are specific to each label specification, including the IC tag type and antenna design. This combines with additional verification and checking features in the Toshiba RFID printer to help to ensure repeatable product quality and consistency from batch to batch.