Moisture meters come in two varieties: pin and pinless. A pin moisture meter can provide quantifiable results but needs to pierce the surface to take measurements; a pinless moisture meter is faster and non-destructive, but only provides a relative reading.

Pin Moisture Meters

Pin moisture measurement requires the physical insertion of the two pin probes into the wall (or material in question). Then an electrical current is run between the two probes, and the material’s moisture content is determined by measuring the resistance the current encounters. Water, with its dissolved salts and impurities, conducts electricity while building materials such as wood do not, meaning dry walls and floors offer more resistance. The wetter the material, the more conductive it is.

Because pin meters are sensitive to temperature and the type of material being measured, a good meter should come with options to compensate for the temperature and material encountered. The FLIR MR55, for instance, comes with a built-in library of 11 different material groups and automatically compensates for ambient temperature.

The takeaway: pin moisture meters provide you with a quantifiable measurement of the percentage of moisture in a material, but require some damage to the material being measured.

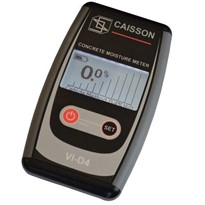

Pinless Moisture Meters

The advantage of pinless moisture meters is they won't damage your walls—but there's a catch. A pinless meter is a “relative” or unitless measurement device. Unlike a pin moisture meter that measures resistance, the pinless meter measures an electrical property of the material called relative permittivity.

To fully understand this measurement, it needs to be compared to a known dry sample of the same material. The best way to use a pinless meter is to make a measurement of a material of a known dryness, then make a measurement of an item of the same material, thickness, and construction.

Any rise in reading indicates moisture, or the presence of some other conductor or high permittivity material (a metal stud behind the wall, for instance, would produce high readings). Because of this, taking multiple measurements over the suspected area is highly recommended.

Pinless moisture meters may have a flat sensor that needs to be placed flush against the surface of the material, or may have a ball probe like the FLIR MR59 that allows you to easily measure into corners and around baseboards.

If you think you need both a pin and pinless moisture meter for your work, then the FLIR MR60 provides both an integrated pinless sensor and an external pin probe.

Infrared Guided Measurement

Another feature you may want to consider on a moisture meter is thermal imaging. FLIR meters equipped with Infrared Guided Measurement (IGM) use thermal imaging to help quickly locate potential moisture issues. Instead of hunting around for hidden leaks or signs of moisture, you can scan large areas to visually target the problem and then either verify it using the built-in pinless meter or an accessory pin probe.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)