The lifting and lashing industry in Australia use a range of equipment for lifting and lashing applications. There are a variety of lifting products that cater to the many requirements to lift, lash, move, and position loads.

Some of the different types of slings available in Australia are chain slings, wire rope slings, woven slings, synthetic slings, webbing slings and synthetic rope slings.

Choosing the right sling is dependent on factors such as:

- Selecting Working Load Limit – This depends on the mass, available headroom, centre of gravity & type of load to be lifted

- Frequency of Use – It is important to ensure the frequency of use because this will determine the longevity of a sling

- Headroom – This is the space between top of the load and the crane hook. Depending on the lifting requirements, adjustable sling lengths or a lifting beam may be required

- Slinging Method – To determine if the slings need to be shackled to the lifting points in a multi-leg application or not

- Environment – It is very important to consider if environmental factors such as the temperature, chemicals, water, or dirt that will influence sling performance

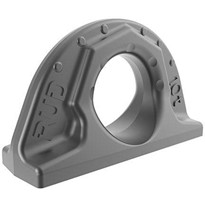

RUD ICE (Innovative Chain Evolution) Chain uses high quality alloy steel that is quenched and tempered during the manufacturing process. A RUD ICE-chain is Grade 120 and can replace a Grade 80 chain of the next nominal chain size. This is due to the high strength of the patented material which makes it possible to achieve the nominal thickness even with a diameter of less than 16mm.

RUD ICE Grade 120 offers 30% reduction in weight compared to Grade 80 chain, using less material due to its light construction and easier handling. Grade 120 Chains possess a 60% stronger breaking force than Grade 80 chains, are extremely robust, tough, and resilient to sharp and rough edge. The reduction in weight of more than 30% is a major advantage for manual handling.

Chain slings can be configured in 1, 2, 3 or 4 legs and in a variety of lengths. Slings can be assembled with different attachments including master and connecting links, joiners, tensioners, clevis sling, grab shortening and self-locking hooks. Advantages of RUD ICE Chain Slings:

- RUD chain slings can be used in harsh operating environments (from -60°c to +300°c) due to their high-strength, durability, and flexible design

- RUD chain slings are resistant to corrosion and UV exposure, and they are also not affected by oil, or grease

- RUD chain slings are lightweight and easy to handle which prevents manual handling injuries caused due to heavy lifting

- RUD chain slings have greater wear resistance and lighter in weight for the same WLL

- RUD chain slings are proof tested and certified

Summary

When choosing a lifting sling, importance should be given to a range of factors to not only ensure safety but also quality, reliability, and consistent performance. RUD chain slings are made in Germany and assembled/proof load tested in Australia – meaning you have peace of mind knowing that the sling is safe and able to perform the job it is designed for – lifting safely in accordance with Australian standards.

We provide lifting solutions through an extensive Australia-wide distributor network servicing geographically dispersed and highly demanding industries.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

-160x160-state_article-rel-cat.png)