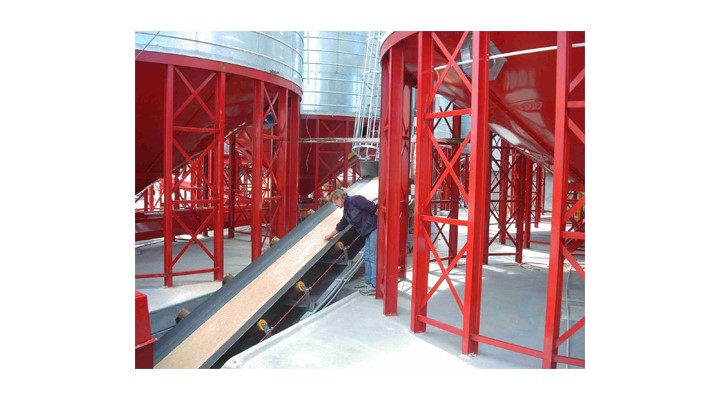

The Company makes use of a number of Silos, Conveyor Belts, Bucket Elevators, Rotary Distributors, Drying Oven and a Cleaning set-up to process Grain and Canola for external customers. The majority of Grain that is produced in Western Australia will be stored for a period of time. Prior to this storage, the grain may require cleaning and drying. This facility offers this to many of the local producers in the area.

Scope

Industrial Automation is to design, supply and install the Conveyor, Elevator and Silo Control System for the grain handling needs. This includes the design, supply and installation of a Motor Control Centre Control System PLC, Operator Interface Panel and Soft Starter equipment. It also includes the supply and calibration of the grain temperature probes. IA is also responsible for the Field mounted Proximity switches for Silo full indication and blocked chutes on Rotary Distributors.

Equipment used

- 10" Quick Panel touch screen

- Sixnet RTU (IPm 1410)

- Sixnet Sixtrack & RemoteTRAK I/O Modules (144 I/O)

- IA Telemetry equipment

- ISaGraf Programming Package

- Soft Start and other Motor Control equipment

End result

The Phase 1 system allows a user to control all Conveyors and Elevators, from a touch screen on a centralised PLC operating system.

Manual Controls are provided to Conveyors for maintenance override purposes.

Field mounted telemetry provides status monitoring and some control functionality, this will be reprogrammed within Phase II, with additional equipment to provide a fully automated system.

The dryer system has already been integrated into the control package with allowance being made for the integration of the cleaning control at a later date.

The touch screen Operator Interface provides the Operator with the following functions:

- Check current temp

- View system alarms

- Check status of Silos and Conveyors

- Control Conveyors / Elevators

- Shutdown System

-205x205.jpg)

-205x205.jpg)