To meet the increasing requirements for energy efficiency and flexibility in modern process manufacturing, information about processes and plant statuses is required which can be exchanged across systems. To achieve this, sensors, devices, control systems and production plants have to be networked horizontally and vertically. The transmission of data beyond the pure process value and its integration into higherlevel systems requires digital communication based on interoperable standards. Emerson, the US based global technology and engineering

corporation, helps customers in process and hybrid industries as well as discrete manufacturing to face these challenges. The company combines state-of-the-art technologies with industry-specific services in the fields of engineering, consulting, project management and maintenance. Many customers around the globe utilize Emerson’s DeltaV and Ovation control systems for process automation. In addition, these customers use Emerson’s AMS (Asset Management Software) Device Manager to troubleshoot, diagnose, and commission the field devices connected to Emerson process automation systems.

AMS Device Manager is used for predictive maintenance and monitoring of intelligent field devices in order to maintain asset reliability and avoid production interruptions and surprise outages. In process industries where lost production from slower startups and longer downtimes can cause millions of dollars in lost revenue, plant personnel need accurate, real-time information. All of this is possible because AMS Device Manager is an integral part of the DeltaV and Ovation process automation systems.

Device management for previously unreachable devices

"AMS Device Manager is the leading asset management system on the market because you can manage, troubleshoot, configure, and calibrate your devices using one software application", says Marcos Peluso, Distinguished Technologist/PlantWeb Technology at Emerson in Eden Prairie. But, the question for Emerson remained how to monitor smart valves and transmitters with AMS Device Manager that are connected to 3rd party control systems or PLCs. There are islands of valves and transmitters around the plant that are not connected to DeltaV or Ovation. Troubleshooting, diagnosing, and commissioning these islands of field devices is still just as important.

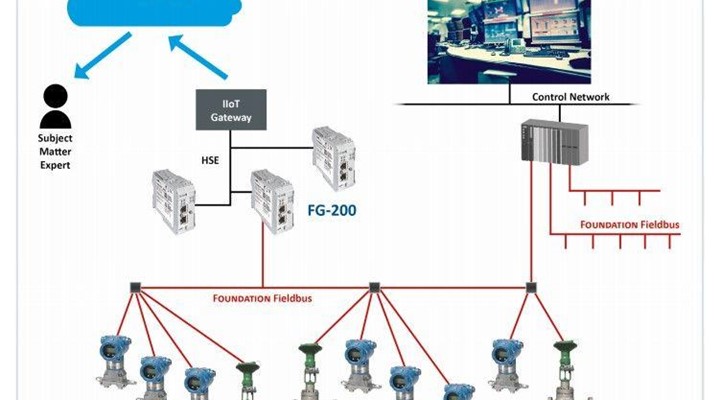

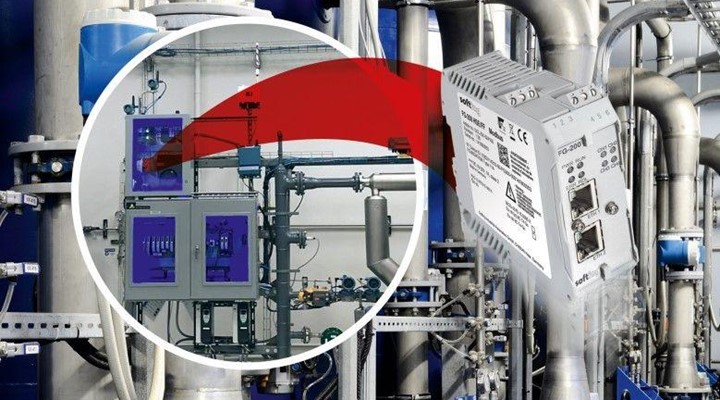

Emerson saw the need to connect AMS Device Manager to those stranded field devices and recognized that the Softing FG-200 gateway

could talk to FOUNDATION Fieldbus H1 devices. So, Emerson and Softing collaborated on the integration of FG-200 and AMS Device Manager, and Emerson developed a driver to integrate FG-200 natively with AMS Device Manager. Early on, Emerson recognized that the FG-200 would be a good fit due to the ability for FG-200 to operate redundantly, its suitability for use in hazardous areas, and its ability to integrate up to four FOUNDATION Fieldbus (FF) H1 links with Modbus support into control and plant asset management systems.

The collaboration resulted in the Softing FG-200 extending connectivity of AMS Device Manager to FOUNDATION Fieldbus devices where third-party control systems are used. The FG-200 is an approved product of Emerson’s DeltaV Alliance Product Programand enables device asset management for Emerson customers in areas beyond just the assets connected to Emerson’s DeltaV and Ovation control systems. Via the FG-200 gateway, Emerson's AMS Device Manager directly accesses process data from FOUNDATION Fieldbus devices connected to third party devices and third party control systems. Surprise outages can now be eliminated where these islands have been eliminated, and

these valves and transmitters are now monitored.

“This is an enormous advantage, because this data is otherwise non-accessible since it is processed in the control system and is not made available to external systems, or only to a limited extent," continues Marcos Peluso. "The FG-200 supports all communication functions of FOUNDATION Fieldbus. Through Modbus or FF-HSE, FG-200 enables unrestricted access to all process data and device parameters regardless of the control system used," adds Thomas Hilz, Strategic Account Manager at Softing Industrial Automation in Haar near Munich.

Remote asset management by subject matter experts

Marcos Peluso sees another customer challenge associated with asset management, “Increasingly, cell phones, and more specifically apps,

offer a plethora of new add-on diagnostic functions that help customers better operate their production facilities.” Most of these apps have been developed to increase the reliability and availability of equipment while enabling predictive maintenance and rapid troubleshooting. "The problem is that many companies do not always have specialists onsite who are able to use this information." If a company has such a

specialist, they are often not available around the clock, or they must travel from far away.

The possibility of remote access eliminates such problems. AMS Device Manager together with FG-200 provides a remote user access to field

device diagnostics from anywhere in the world. This is particularly valuable for devices that provide more sophisticated diagnostic data, such as positioners for valves, and large components such as heat exchangers, pumps, compressors, fans and cooling towers. Remote access and analysis of relevant data can save time and money and prevent production downtime. "It’s hard to generalize the cost savings because it depends on many components, the type of application and the equipment," says Marcos Peluso. "Reports show that predicting a valve failure and thus preventing a surprise shutdown of a process can save millions of dollars in lost revenue and repair costs."

Deane Horn, Director of Product Management for Softing North America and contact for the DeltaV Alliance Product Program says, “Remote

analysis can be valuable from a number of perspectives. Enterprise field instrument experts within the company can help diagnose field devices, and in addition, can provide a second opinion during troubleshooting, especially as a younger work force may be coming up to speed. Remote connectivity can also enable Emerson Connected Services outside of your company where you just don’t have the manpower to adequately manage your intelligent field devices.”

Bottom-line:

AMS Device Manager together with DeltaV and Ovation is a powerful combination for managing intelligent valves and transmitters and helps

to decrease maintenance costs and increase reliability. Since not all critical and essential smart field devices are connected to DeltaV and Ovation, AMS Device Manager requires another type of solution to reach stranded field devices. FG-200 enables AMS Device Manager

to reach those stranded field devices so users are no longer limited to managing only devices connected through DeltaV and Ovation. FG-200 provides the added capability of enabling remote management of intelligent field devices by enterprise experts that might be anywhere in the world. FG-200 extends the reach of device management across the plant floor and extends device management out to enterprise subject matter experts.

-160x160-state_article-rel-cat.png)