Where the story began

In 1946, after the Second World War, a major textile manufacturing plant was built in North-Eastern Victoria. Textile manufacturing uses a lot of water, and so wastewater infrastructure was required as part of the original set up all those years ago.

Nearby the factory site there is a Major Trade waste pump station that receives the textile waste, managed by North East Water.

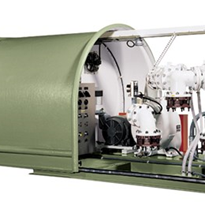

North East Water had to ensure the WWTP had the capability to manage the waste from the textile plant. A Gorman-Rupp pump T8 A3 – B was installed a few years after the textile plant was built, and this pump was pumping the wastewater from the Trade Waste pump station to the Trade Waste treatment plant which is 2.1Kms of 300mm pipe.

In the busy periods of its career, this Gorman-Rupp self-priming pump would be operating for around 12 hours a day at 115 Litres per second. In its peak periods, it would pump 5 ML a day 5 days a week.

One year when production peaked it pumped 2000ML in a year – that’s 5.5Ml EVERY DAY FOR AN ENTIRE YEAR!

The textile factory is owned by a progressive company that pivoted during the 80’s and 90’s to create innovative, high-quality technical textiles when tarrifs from China were reduced and fashion fabrics became too expensive to produce in Australia.

A variety of solids strewn and lightly corrosive wastewaters come through this pump to the WWTP every year. For over 50 years, there have been constant demands placed on this durable Gorman-Rupp pump.

Unbelievably, this same pump is still in use today, and currently pumps 1.5-3ML a week.

About the pump

Even more remarkable, during its long and dependable life, this pump has had no issues. Each year, when the pump was doing major flows, it would receive an annual service. This would include replacing the impeller due to it wearing down from abrasion and minor chemical attack, replacing the mechanical seal and a new set of bearings. Because the pump is a surface mounted self-priming pump, maintenance is simple and easy, and only requires 1 operator and two spanners.

Imagine foreseeing when the facility was built that some of the original equipment installed would still be in use today, in 2020. In an age when we are so digitally connected, it is great to see that the simple and solid construction of quality and dependable Gorman-Rupp pump is as relevant today as it was 50 years ago. Gorman-Rupp are American made and are close to manufacturing their 2,000,000th pump after 85 years in business. They have an impeccable track record for designing and manufacturing rugged and reliable, surface mounted self-priming pumps.

Quality of Gorman-Rupp pumps

Not only are Gorman-Rupp pumps durable and reliable, when maintenance is required, it is such a simple exercise because the pumps are above ground and so easily accessed. No cranes, no large team of certified specialists, and no pumps out of action for long periods of time. All maintenance can be carried out by one operator in a short time, without exposure to the wet well or its contents.

Where it is up to today

Matt LePoidevin, the Treatment Operator at North East Water says this particular pump has pumped over 60,000ML in its lifetime. Matt knows well how rugged and dependable Gorman-Rupp surface-mounted self-priming pumps are, and they are his pump of choice for use in the busy wastewater treatment plant run by North East Water.

Hydro Innovations are proud to be the Australian Distributor for Gorman-Rupp Pumps for 13 years.

-160x160-state_article-rel-cat.png)

-205x205.jpg)