While FLIR OGI cameras are extremely sensitive and can detect gas leaks up to hundreds of meters away, sometimes a leak that’s particularly small or distant requires something extra to be visualized. Using a feature called high sensitivity mode (HSM), operators can spot even the smallest of leaks.

Enhancing Gas Leak Detection

High sensitivity mode is a patented image subtraction video processing technique that enhances the thermal sensitivity of the camera. The HSM feature subtracts a percentage of individual pixel signals from frames in the video stream from the subsequent frames. This enhances the differences between frames and makes leaks stand out more clearly in the resulting images.

Using HSM gives the user control over the amount of compensation applied to the video stream, and therefore the degree of increase in thermal sensitivity. In the below video, for example, the vapors emitted from hand sanitizer become much more obvious when the camera is switched to HSM:

Hand sanitizer containing ethyl alcohol releases invisible vapors that can be visualized with a FLIR GF320 gas detection camera.

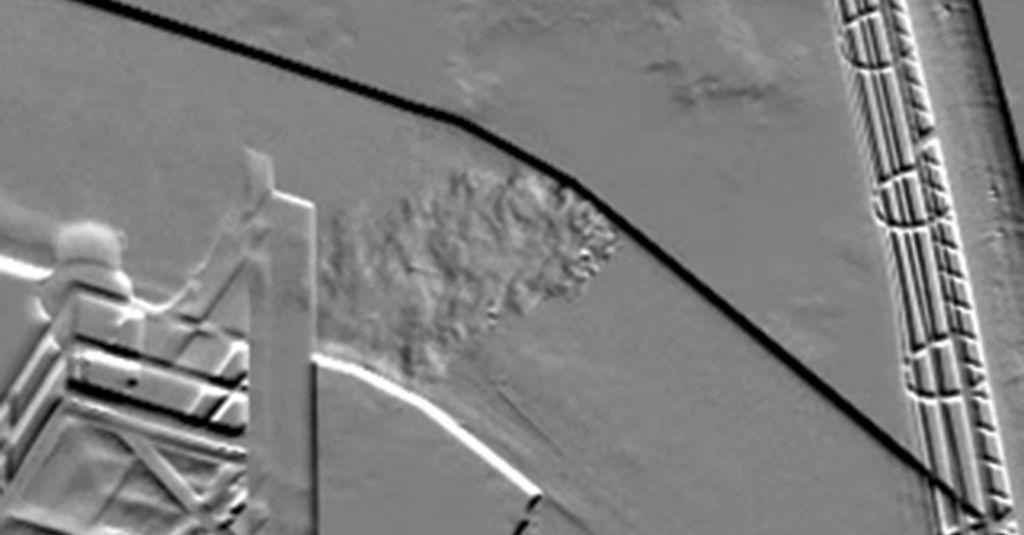

Of course, usually camera operators are looking for gas leaks from sources much further away than shown in this clip, either because it's impractical to get closer, or because hazardous conditions prevent approaching the source of the leak. Unlike many other inspection tools, OGI cameras offer the ability to visualize unsafe conditions from a safe distance. HSM allows the user to see even smaller leaks from a greater distance compared to the "normal" infrared mode:

The FLIR GF620 can detect methane and other volatile organic compound (VOC) emissions from a safe distance.

Saving Time in the Field

Setting the appropriate temperature span and level (mid-point) is usually essential to obtaining the required optical gas imaging results. (A wide span will provide less image detail while a narrow, more fine-tuned span will offer more detail.) HSM mode, however, enables users to search for gas without having to set the level of the image before narrowing the span.

Since setting the level to the background temperature is a complicated process and not possible for more than one background at a time, HSM allows maintenance engineers or operators to save tons of time and makes it much easier and faster for them to search for small leaks. This is done in real time and therefore greatly enhances the stability and sensitivity of gas detection cameras.

Enhancing the stability also means that in HSM, the camera can be moved while in use, instead of requiring a tripod to stabilize.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)