Achieving long-term success with a CNC press brake machine requires a combination of factors, including proper machine maintenance, operator training, process optimization, and effective safety measures. Here are some essential tips to help you enjoy long-term success with your CNC press brake machine:

Quality Machine Selection: Invest in a high-quality CNC press brake machine from a reputable manufacturer. A well-built machine will offer better reliability and longevity.

Regular Maintenance: Create a comprehensive maintenance schedule and follow it diligently. Regularly inspect and clean the machine, including its tooling, to prevent wear and tear. Address any issues promptly to avoid costly breakdowns and downtime.

Operator Training: Properly train your CNC press brake machine operators to ensure they understand the machine's capabilities, programming, and safety protocols. Skilled operators can optimize the machine's performance and reduce the risk of accidents.

Tooling and Material Selection: Use high-quality tooling appropriate for your bending tasks. Different materials require specific tooling to achieve optimal results and prevent damage to the machine or tooling.

Workpiece Programming and Setup: Optimize your bending process by using efficient programming and setup techniques. Modern CNC press brake machines often have advanced software that allows for simulation and offline programming, which helps reduce setup times and minimizes errors.

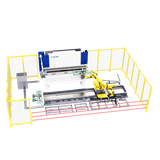

Safety Measures: Prioritize safety in your workshop. Ensure that your operators are equipped with proper safety gear and are trained on safe machine operation. Implement safety features on the press brake, such as laser guards, two-hand controls, and emergency stops.

Monitor Machine Performance: Keep track of the machine's performance over time. Analyze production data to identify trends, optimize processes, and identify potential issues before they become significant problems.

Regular Calibration: Regularly calibrate the CNC press brake to ensure accurate bending angles and consistent results. Calibration is essential to maintaining high-quality outputs and reducing waste.

Preventive Repairs: Don't wait for parts to fail completely before replacing them. Stay ahead of potential issues by carrying out preventive repairs and replacing worn components as needed

Continuous Learning: Stay updated with the latest advancements in CNC press brake technology and techniques. Attend workshops, seminars, and training sessions to keep your operators and maintenance staff well-informed.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)