Moving animal waste sludge can be a difficult proposition for pumps. It can be thick and corrosive, and is definitely only a job for the right pump. As the waste liquid gets thicker, it becomes much less efficient to use a centrifugal pump, but the right peristaltic pump is an ideal solution. Italian made Ragazzini brand hose pumps, distributed by Hydro Innovations, can move thick slurry comfortably when sized correctly and fitted with the right tubular element.

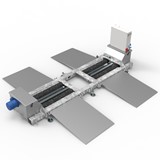

Ragazzini “Rotho” pumps use a roller on bearing method to “squeeze” the tubular element, creating a vacuum on the suction side, enabling pumps to operate on high suction lifts. The pumps are also capable of delivering pressures up to 15 bar, enabling them to “push” the sludge material over high static lifts or through long pipe lines. These pumps are fitted with a leak detection system that will stop the pump and send an alarm if the hose wears. This is a float type sensor that is located at the lowest point in the pump.

The pumps have no seals or valves to maintain, can run dry without damage, and there is no contact between the pumped media and moving parts. Ragazzini pumps are designed to run slowly to promote longer hose life and they are able to pump liquids of sludge containing solid particles. Flows from just a few litres per minute up to 180m3/hour can be delivered, depending on pump model.

Ragazzini peristaltic pumps are available with a wide variety of hose options to suit abrasive and/or corrosive applications and are also available with food-grade hoses capable of being sterilized with hot water [to 70o] and/or steam [to 120o]. Because the pump casing is not filled with lubricating fluid and the speed of the leak detector, contamination is prevented and product loss is greatly minimised.

These pumps are perfect for clean in place [CIP] or sanitise in place [SIP] applications when fitted with the optional “retractable roller”. With this system, one of the rollers can be retracted via an over-centre rapid release cam and lever system. This now enables the full flow of a flushing/cleaning/sanitising fluid through the hose. This new positioning system is essential for fully automated foodstuff handling applications that require regular cleaning and sterilisation of all the components in contact with the product.

Ragazzini pumps can also be run in reverse, making them ideal for tank emptying and filling operations.

Ragazzini pumps do not need the casing to be filled with lubrication fluid. This reduces the chances of contamination and makes hose changes cleaner, quicker, safer and cheaper.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)