Numerous belting options are being considered then rejected. All things considered, there's a lot resting on this selection process. Is a fibre-reinforced synthetic rubber right for the job? Maybe we're looking at specially graded stainless steel? Just how is this selection process resolved?

Weighing the Flexible Options

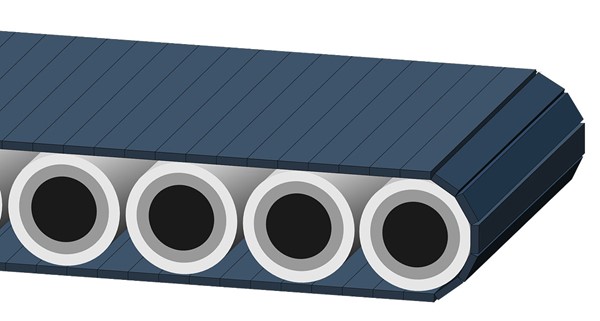

That's a lot of questions, but there are no answers, not so far. Well, the first step is to study the production line. If this isn't a food-safe area, nor is it a heavily loaded belt deck, then a reinforced rubber with a raised profile will work well. But wait, there are oils and fluids spotting the belt. Ensure the chosen engineering plastic is oil resistant. And, should those loads include sharp edges, select a polymer that's cut and abrasion resistant.

Selecting Profiled Metal Assemblages

Employed on heavier item conveyance lines, these are the stainless steel rollers and slotted metal belts that transport coarser loads. They're durable, not affected by corrosive materials or high temperatures, and industrially-scaled objects are not an issue. Metal-lined conveyor systems also handle drop impact, which is a feature slighter rubberized belts lack. Wear-resistant by design, chains and gear trains power the rollers. Alternatively, the belts are shaped as woven wire ribbons. This latter configuration is easy to wash, so it's commonly utilized in the food sector.

Meet the Stainless Steel Options

This is when we turn to the graded stainless steel families. This being the case, a 301HY alloy creates supremely rugged stainless steel conveyor segments and rollers. If belt durability isn't the issue, what about a corrosion resistant member of the family? In this case, 316 stainless is the solution. Then there's Titanium and Inconel, a pair of super-strong, oxidization repellent metal bases, which can hold the heaviest conveyance loads. Adding insult to injury, thermal persecution is last on the list of environmental hazards. Again, graded alloys come to the rescue. By name, we're referring to the belt materials that feature a lower thermal expansion coefficient, such as Invar 36 or 17-7 PH Stainless Steel, CH900.

Conveyor belt materials come in numerous forms. That standard rubberized form factor, for example, can withstand all kinds of fluid contaminants and dense loads as long as the correct polymer is selected. Bolster that selection by adding a fibre-backed lining and a raised profile. Then, if a durable alloy is the only viable option, opt for one of the many alloys mentioned above. Just make sure the selected alloy is equipped to deal with heat and a corrosive environment.

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.jpg)

-205x205.jpg)