"Digitisation", "Internet of Things", "Industry 4.0" and "Smart Production" – all these buzz words are no longer terms that are used in purely academic discussion forums but are now gradually becoming part of the normal everyday life of companies. Thanks to 'deep learning', robots used in production are already performing complex tasks whereas tablets and similar devices are almost taken for granted as part of the basic equipment of project managers and maintenance personnel. This development is characterised by the fact that data is the new key currency, generating and evaluating data is now a central task.

Digitalisation began with an idea that has become known as the "Internet of Things" (IoT) which involves the interconnection of physical and virtual objects within a global infrastructure. A simple example: a printer cartridge that is approaching empty and two mouse clicks are enough to ensure that a replacement is delivered. The objective is to make the networking of production systems, products and people, production or distribution more efficient. Accordingly, machines communicate with each other and exchange information on status, workpieces and potential error messages.

Intelligent igus smart plastics help create smart factories

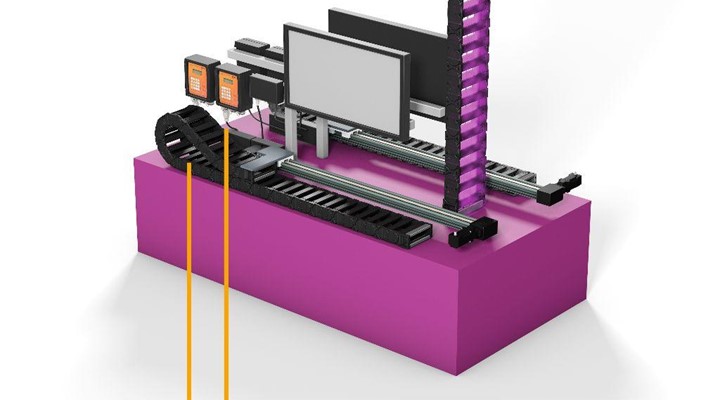

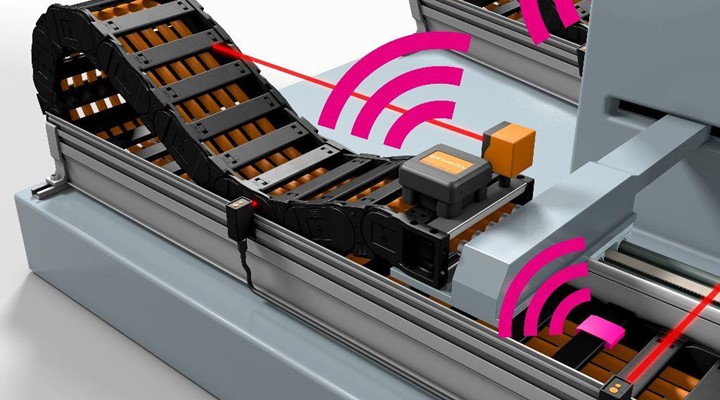

As a manufacturer and supplier of components made of high-performance plastics such as energy chains, cables and bearings, igus is also going through a digital development process and is increasingly orienting its products towards use in smart factories. The aim is to make the maintenance and repair of its plastics more efficient and cost-effective. The new isense family of sensors and monitoring products have been developed, making igus plastic products into intelligent solutions, so-called smart plastics. The result is that these components do not simply develop a defect unexpectedly but predict this defect and indicate a need for maintenance beforehand. With this new development, igus offers predictive maintenance - smart production meets equally smart maintenance.

“Early warning system” on the basis of smart predictions

It is easy to explain the principle of smart plastics: sensors of many different kinds detect the condition of the igus components, energy chains, cables or linear bearings and slewing rings and communicate their condition to a data concentrator (icom module) which then passes this data on to an intelligent system. In this way, the push and pull forces acting on e-chains, for example, can be monitored during ongoing operation and maintenance work can be performed on them before a malfunction occurs. This makes it possible to avoid the worst-case scenario – plant downtime and an interruption to production. Also, maintenance and service assignments become more predictable and therefore more efficient. Trades where there are a large number of chains in use benefit not only from these sensors but also from the EC.B, a piece of measuring equipment that detects chain failures. The EC.B sends out a message immediately after the failure occurs. Protracted overloading of the opposite side of the chain is avoided which makes even such service assignments manageable time-wise and prevents the occurrence of consequential damage to further chain links. But for cables as well as e-chains, igus has created means of preventive monitoring, including the CF.Q, which measures the electrical properties of cables. Recently, igus presented a novel and globally unique concept for the intelligent monitoring of bus cables in e-chain systems. Thanks to early alerts, even in the case of the slightest changes in transmission characteristics, the CF.D system detects imminent plant shutdowns in good time.

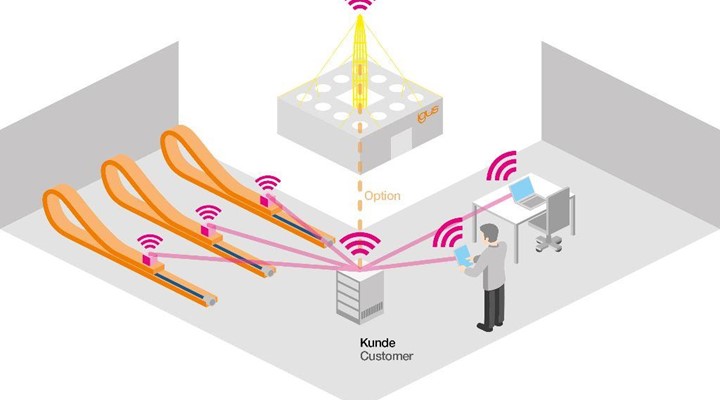

Online: predictive maintenance by connecting to the igus server

Once the measured values from a sensor have been transferred to the icom module, they have to be "interpreted", i.e. understood in order to generate instructions. So far, this has been possible via the connection to the igus cloud. With the online connection of the icom, a continuous matching of the service life statement with the igus cloud takes place in order to enable maximum system runtimes with minimal failure risk. As a result, it is now possible for maintenance teams to plan where work is really necessary. Efficient organisation of maintenance work according to priority and thanks to integration into the ERP, with the appropriate replacement part from stock which is provided after the sensor warning. This not only achieves immense cost savings over the long term, but provides assistance to shift supervisors, maintenance crews and even the warehouse team in their day-to-day work. This online connection and a link to the igus CRM system makes it possible for the first time to really predict when maintenance is necessary. This means that fitters receive an e-mail in due time that drives will show wear in the near future, e-chains are threatened by complete failure or should be changed due to their age rather than only being called when the red warning light is notifying a shutdown. Electricians benefit from continuous measurements that signal impending cable breaks and then send a warning by text message (at the planning stage). This makes it possible to organise maintenance work and to set priorities for the first time. Service teams can be put together in an intelligent manner and staffing shortages (and consequently complete failures) can be reliably avoided. In order to achieve smart warehousing and to ensure that the correct quantity of replacement parts is always in stock, an automatic quotation is generated in the igus CRM system at the same time as the pending maintenance message – assuming the customer's consent – which is then communicated to a previously specified contact person (in the sales department, for example) for easy and quick ordering. In practice, this means even more efficient production and maintenance as unavailable or obsolete replacement parts in the customer's inventory are a thing of the past thanks to interaction with igus CRM. But much more is possible with the online connection: data from the igus laboratory is processed on a server with the anonymised customer data and also with open data of other customer applications in order to produce a data model. All of this is done using advanced machine learning strategies, that leverage complex algorithms, to create "weak" artificial intelligence. The result: a data-based "electronic design manual", which retrieves the service life calculation from the protected customer area. All data that is recorded by built-in sensors on chains, cables and plain bearings is entered in the (anonymised) igus test data base, upon request. From this data pool, which has grown over decades, igus is currently able to determine in advance the nominal/reference values for the operating states of e-chains, stressed chainflex cables and plain bearings: thousands of existing datasets in combination with new datasets form smart structures, known as neural networks that are able to learn from the data – in a similar way to the human brain.

Offline: flexible data connection through new 3-in-1 module

Due to the increasing importance of IT security, many companies are increasingly relying on the development of their own SCADA systems, which is why igus has now advanced its data concentrator into icom.plus. With the new module, the customer can integrate the data in the way that best suits their equipment. The icom.plus is programmed via igus online configurations with initial service life algorithms. The special feature: the new communication module can be operated offline upon customer request, after online installation without update function. In this "semi-offline" case, during an initial "learning phase", the device requires a temporary, short-term secured IoT access to the igus server to match the calculation algorithms to the actual motion and environmental profile of the customer application. In very restrictive areas, the update can also be performed from the beginning via a storage medium completely offline. The user can therefore decide how the module is connected and how the data is managed, while establishing a balance between runtime maximisation and IT security. The motion profile required for the calculation of the maintenance recommendation is read directly from the control system via the bus system of the machine. In the same way, the information about the number of days until the next recommended maintenance and freely definable warning messages about unusual changes in the sensor data are transferred to the PLC control. The user information is provided directly via the system monitor or via customer-specific SCADA systems.

Conclusion: new era in terms of maintenance and repair work

Irrespective of whether the customer chooses the online or offline version for maintenance and repair, the digitisation of mechanical products offers potential that has never previously existed. Also because they can have an effect on a product's entire value added chain. Greater use of smart technologies will make day-to-day work more efficient and easier in future. Predictive maintenance will develop in line with digitalisation and will become an integral part of Industry 4.0 in the foreseeable future. Efficient and therefore successful maintenance – whether in the automotive, mechanical engineering, chemical or pharmaceutical industries – will be characterised in future by two factors: firstly, the interaction of historically developed practical knowledge and newly acquired digital know-how and secondly by the art of how to exploit both aspects.

The whole range of igus smart plastics is available from Treotham. Speak with someone from Treotham today for more information.