In some instances there may be a material cost increase by using Pryda floor trusses over alternative flooring systems.

However when it comes to installing the product Pryda floor trusses can provide significant labour savings. In addition, floor trusses have some considerable design advantages that could result in reducing the need for a large amount of costly structural support construction. E.g. Long spans may reduce the need for internal load bearing walls.

Go to the PowerPoint presentation in this section to view the St. Clair Park Village case study. There was a 6% increase in material costs by using Pryda Longreach floor trusses over solid joists. Framing time was reduced by 2 weeks and the labour saving was 2.5 times larger than the material cost increase.

Examples of these advantages are as follows and should be considered in the assessment of the overall cost of the flooring system:

Design Cost Savings

- Cost Efficient Design. Each floor truss is customised for the job, including required stiffness, depth, timber grades and span. It will be computer designed for optimal performance and cost and installation efficiency while minimizing waste.

- Significant Design Improvement with Minimal Cost Increases. Span capacity and stiffness can be significantly enhanced by simply increasing the depth of the Pryda Longreach floor truss. Due to the timber web design of the floor trusses, the increase in depth is at a minimal cost.

- Greater Design Flexibility. Extra long spans and large cantilevers can be provided, with the ability to support high loads. Spans up to 7.1 metres at 400mm depth using MGP12 pine can be achieved. This results in the following design and cost benefits:

- The long spans can potentially eliminate the need for some interior support walls and beams, giving more scope to architects and designers thus reducing the cost of the support structure.

- Large spans within restricted height applications can be achieved. In some cases the use of floor trusses may eliminate the need to use costly steel beams.

- Ideal for sloping blocks. In some instances floor trusses could be used to eliminate or reduce the excavation costs associated with sloping blocks.

Labour Cost Savings

- Set-down or Recess sections. The ability to design and manufacture set down sections into the floor trusses provides significant labour savings in the following situations:

- In cantilever and balcony areas where the provision of adequate flashing and accommodation of different floor covering material thicknesses is critical.

- Bathrooms, toilets and other wet areas may also require the floor surface to be set-down. This will provide significant labour savings when other trades start installing bathroom fixtures, fittings and tiling.

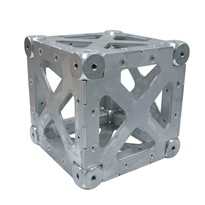

- No Cutting, Drilling or Notching.T he open webs allow easy fixing of electrical, plumbing, ducts and energy services. There is no need for drilling or notching, saving time on site.

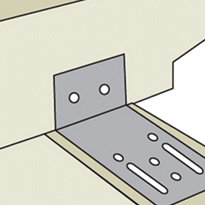

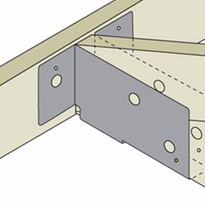

- Quick Installation. A large selection of end support types for quick and easy installation. Pryda floor trusses arrive on site Manufactured to size and ready to install, eliminating the need to trim on site. There is no material or labour wastage. Pryda floor trusses are designed and manufactured with end types for fast, secure fixing to steel, concrete, masonry or timber. Go to the product drawing library to view the available options.