Then, when the movement method is solved, there's the sanitary factor to take into account. As it turns out, this hygiene-centric issue overrules all other considerations. On the strength of this demand for site sterility, what essential features must be incorporated into a sanitary washdown conveyor system?

Facilitating the Clean Cycle

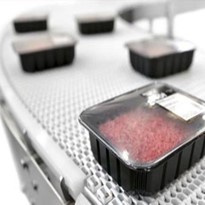

Built for this super-clean detail, washdown ease is addressed here when the chosen belt material is impervious to foodstuff staining. A mild detergent and a water hose are enough to shift any stubborn residues when a dense polymer is employed as the conveyor belt. Better yet, a band of polished stainless steel will reject all sticky food waste. As the name implies, this type of steel is impermeable. For all intents and purposes, the alloy is non-porous, so it won't absorb food-based fluids. Similarly, plastic drive chains use a lubricant-free design to eliminate potential machine-based contaminants.

Food-Grade Mechanisms

Absolutely zero, that's the number of contaminants that are acceptable in a food processing environment. That's why sanitary washdown conveyors are designed to expedite that cleaning cycle. Crevices are eliminated from the design, then drainage ports are cut into the equipment. The non-porous alloy prevents sticky sauces and raw meat juices from penetrating the structural core of the belt line, then the streamlined frame encourages an effective washdown operation. As the cleaning agent sluices through the machine, its belt drive and rollers, the drainage ports quickly funnel the dirty water towards a site outflow conduit.

Know Thy Enemy: Corrosion and Bacteria

Essentially, sanitary washdown conveyors don't breed bacteria. Given half a chance, an unworthy mechanism will allow bacteria to flourish in some nook or cranny. Likewise, a substandard alloy will begin to corrode because it's constantly exposed to these cleaning mediums. Washed down regularly, a refined material finish won't corrode, nor will it allow bacteria any purchase. By the way, some of those juices, be they fruit or meat-based, are packed with acidic compounds. In this case, a plastic belt will safely convey its food-based load, but it won't last long, not when there are caustic substances carried on the belt.

Even stainless steel has trouble when these foodstuffs turn aggressive. Heavy salts and strong food acids will corrode grade 304 stainless steel. Choose corrosion-resistant grade 316 stainless steel when these harsher foodstuffs are nearby. Otherwise, choose a polished alloy or a dense polymer, materials that wash easily and never stain. Finish the design by ensuring the conveyor framework is equipped with a quick fluid drainage feature.

-160x160-state_article-rel-cat.png)