"It’s true to say we’ve had a love-hate relationship with noise loggers. Our first encounter with them was at the Water UK Leakage Conference 2016. As a company we had specialised in finding partially billed commercial properties for over a decade. But by 2016, we’d begun more and more to pinpoint non-visible network and customer-side leaks. Thus the need to invest in good quality leakage equipment arose. Enter a beaming Paul Chandler, who was stood at the Gutermann conference stand. Paul introduced us to the technology and it seemed like something we should try out. Firstly, let me say that the ZONESCAN 820 noise loggers are an excellent product for reducing leakage in a cost effective manner. They’re an important part of our toolkit.

The following is a description of a full ‘unboxing’ of the ZONESCAN 820 loggers, written by someone who has deployed them and, more importantly, used the data to find points of interest and carried out follow up surveys on those points of interest.

First trial – love at first sight

Following the conference, Paul was only too happy to come to our offices and lend us a case of his ZONESCAN 820 correlating noise loggers. He taught us how to use them, gave us some advice about interpreting the data and left them with us for a week to have a play. I would be lying to you if I said we had no teething issues whatsoever. The loggers are very easy to use, but there are a few user-error pitfalls you have to learn to avoid. For example, if you want the loggers to correlate you need to “Program Initially” before you deploy. (Paul had told us this.) These pitfalls are few - especially for water industry kit. After a couple of deployments you know the system back to front. We’ve also created a simple check sheet for the team deploying the loggers which ensures they do not forget the key steps.

What’s it like deploying the loggers?

We deployed the loggers around some DMAs. And they did what we expected them to. They found some leaks. Deploying the loggers is brilliantly easy. You just need an android phone with the Zonescan app on it. You go to the area of deployment. Lift the valve or hydrant chamber. Scan the barcode of the logger you wish to deploy. Stick it on the valve or hydrant using the magnetic bottom of the logger. And that’s it. As you scan the logger, the system collects your GPS co-ordinates so you don’t have to do anything like this yourself. This means the data goes straight onto a map later on. Collecting the loggers is just as easy. You just pick the logger out of the pit, scan the barcode and it lets you know you’ve collected that logger. Once they’re all collected, you can push the data in about five minutes up to the cloud. Then it’s available for anyone to log in and analyse what you’ve done. A full box of 40 loggers weighs about 20kg. About one in fifty times the logger will be too big to fit on a line valve – mainly if the valve is very shallow. I’ve never seen a logger that can’t fit into a hydrant pit. Because the ZONESCAN 820s for lift & shift rely on manual downloads, there’s no need to consider phone signal etc.

Around the time of the trial we also bought a competitor’s set of noise loggers, so we had something to compare them to (they wouldn't let us have a trial kit for free so we have to by a set to find out they weren't any good). The difference between Gutermann’s and the competitor’s was night and day. Gutermann’s were so much easier to deploy and get the crucial leakage information. The competitor’s set are sat in our storage room and have only been used the once. We deployed the loggers across half a dozen DMAs and they found some points of interest. We followed up on these and found some decent leaks that had clearly run for some time without being detected.

What’s it like analysing the data?

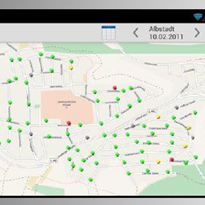

The data gets uploaded to the cloud-based web app Zonescan.net. It’s easy to interpret. The loggers with the best leak scores are coloured red. Low leak scores are green. In between are orange.

It’s very standard colouring, but it works really well and I’ve seen other systems that do not do it as clearly. You can click and listen to a noise file to rule out things like electrical interference. Gutermann run some algorithms against the frequency scores and do a good job of reducing the logger’s leak score when it detects electrical interference. This is a neat feature. You get a noise histogram and a frequency histogram for each logger which I really like. These graphs are very easy to interpret. You can correlate between the loggers, which I’ve never really got on with. This is probably more down to personal preference, however. I personally don’t see the need to correlate at the desktop. I would rather be on site and decide for myself if I want to correlate or not. I find you can use the noise levels to localise the leaks well enough before heading to site. For example if you have two loggers, one reading 40 dB and one reading 30 dB, chances are the leak is nearer the one recording 40 dB. Finally the system is fastest I’ve used for noise logging.

Honeymoon over – why did we fall out of love with the noise loggers?

Having used the loggers for several months, we decided to stop using them. Let me be clear, this wasn’t a reflection of the the Zonescans themselves. It was more a question of: could we be more productive without using noise loggers? Our process at the time was:

1. Tech would sound asset

2. If noisy or unsure, tech would deploy noise logger

3. If quiet tech would not deploy the logger

4. Tech would need to return the next day to retrieve the logger

Why, we asked ourselves, are we going back to site twice – once to deploy and once to retrieve – when the tech’s already sounded the asset and knows if there’s a leak or not? It seemed crazy. We were going back to the same areas twice. We could cover twice the amount of ground if we didn’t deploy the loggers. Also where you got clusters of noisy assets around a leak, we might deploy five or six loggers practically on top of each other. This meant that the desktop analysis was becoming more and more time consuming.

So we changed our process. The loggers were shelved and we returned to what Paul would later refer to as “stickin’”. We noise bashed assets and noted their noise. The new process remained successful. We had found leaks through deploying the noise loggers. And we continued to find leaks through the noise bashing approach.

What made us fall back in love with the loggers?

I’m pleased to report that the Zonescan noise loggers are now a key part of our process, for the following reasons:

1. Errant tech: One of the benefits of being a small company is we only have a small team of site technicians to manage. But one new recruit (who is no longer with us) was hired to do some initial leakage surveys across DMAs. I’m sure you’ll know what I’m going onto say. Some assets which had been ‘surveyed’, patently had not. Line valves under five foot of brambles had been ticked off. Hydrants within a factory car park that was closed for demolition with locked gates had been ticked off. Could we trust anything the tech had done? In a word: no. What if there was a technology that could help us avoid this pitfall?

2. Lots of paper and missing leaks at desktop. Plus we were getting back reams and reams of paper. We were as careful as can be when reviewing the leaks. But we must have missed some that were scrawled on a bit of soggy GIS plan.

3. One man’s ‘big noise’ is another man’s ‘small noise’: The noise bashing approach took us back to a subjective grading of noise. The nice thing about the dB score on the noise loggers is it is a scientific measurement. You don’t have the same subjectivity about how noisy something sounds.

4. The loggers aren’t impacted as much by traffic and wind: Noise bashing on a windy day next to a busy road is pretty thankless. You will struggle to hear anything. The loggers are cocooned in a chamber and protected from the elements to a degree so you are less likely to miss leaks.

5. More wasted time doing follow ups: Because the noise loggers listen at night – over a period of two hours – you get barely any genuine usage. With noise bashing in the day time you can hear good noise because someone’s jumped in the shower. Our follow up crews would return to the noisy asset and say it’s all quiet, which is a wasted visit. Now you don’t know who to believe, which brings us back to point 1.

Happily ever after – why the noise loggers are a key part of our process

So we reviewed our approach once more. The cases of Zonescan loggers were dusted off and we agreed a way to get the best out of them. We agreed a new process for some of the things that had undermined our previous confidence in the technology. These were things like area naming conventions, spacing rules for deployment and ensuring a whole DMA is covered in one day. I’m pleased to say that this seems like the best way of doing an initial survey a DMA for leakage. Yes, the loggers require two visits, one to deploy and one to retrieve. Yes, some loggers get parked over and picked up by other contractors by mistake. And yes, they aren’t the cheapest bits of kit to begin with.

But we’ve established now a process that works for us and still allows us to cost effectively find leaks that have been undetected for many years. All in all I would heartily recommend the Zonescan 820s for anyone looking for a cost-effective way to reduce leakage.

Special mention for the Gutermann team

Paul has always been great to work with. He’s always at the end of the phone if you’ve got a question and has helped us a couple of times where a tech has uploaded data to the wrong area. Paul’s been to site with us twice to demo bits of kit and let us see the pros and cons before we buy. Paul and Steve have also spent a day at our offices explaining to all our techs and analysts how the noise loggers work, how to deploy, how to retrieve and how to analyse. Tony, Paul’s counterpart in the North is also very knowledgeable about the industry too."

Ben Beattie

Teccura Software, Operations Manager

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)