In order to market this through the traditional distribution chain, Modified Atmosphere Packaging (MAP) and Controlled Atmosphere Packaging (CAP) offers the solution to extending the product shelf life during transportation and supermarket retailing.

Modified atmosphere packaging is where the pack atmosphere is altered initially and then allowed to change over time during storage. With controlled atmosphere packaging, the package atmosphere is altered initially and then maintained during the life of the package.

Additionally, previously frozen produce such as meats can now be shipped in the preferred, unfrozen state, long distances and enjoyed with better taste, texture and appearance.

Crucial to this practice is the integrity of the gas seal and the correct operation of the back flushing machinery. Packaging plays a very important role in preserving, protecting and preventing the food from getting spoiled. Faulty packaging can undo all the attempts of preserving the food made by the food processor during the manufacturing process. That is why a food manufacturer must have appropriate knowledge about the different types and functions of packaging. There are a number of packaging techniques and materials available to suit the variant degree of food products in terms of their size, nature, bulk density, and perishability.

Fruits and vegetables consume Oxygen and give off Carbon Dioxide as they ripen. There are three ways to slow down this respiration change. The first one is to reduce the temperature; second, reducing but not eliminating Oxygen; and third, increasing the amount of Carbon Dioxide. Due to the reduction in temperature, the biochemical reactions occurring due to various enzymes, are inhibited. Lowering the amount of Oxygen level leads to inhibition of the growth of spoilage causing microorganisms and increasing the Carbon Dioxide level leads to the killing of microorganisms (e.g. moulds which are aerobic). The optimum temperatures, relative humidity and gas compositions differ for different fruits and vegetables.

Three particular gases – Oxygen, Carbon Dioxide and Nitrogen, play a specific role as mentioned below:

-

Oxygen: Preserves the red colour of meat.

-

Carbon Dioxide: Prevent the development of moulds and bacteria.

-

Nitrogen: Being an inert gas, it prevents respiration and enzymatic activity.

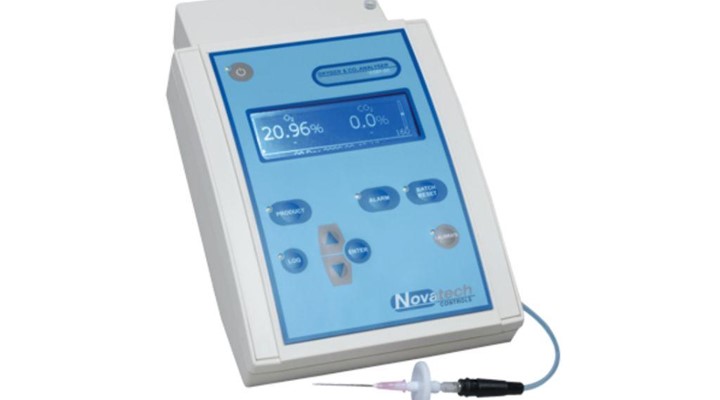

In this article, we’ll discuss two gas analysers from Novatech that are designed for use in the food packaging industry.

The first is the Model 1637 Mk II Oxygen & Carbon Dioxide Analyser

The model 1637 analysers are used to check for the lowest level of oxygen and the highest level of carbon dioxide in the headspace of food packs that have been sealed using MAP or CAP methods of packaging. This measurement is vital to predicting the shelf life of the particular food being packaged.

The oxygen only version of the 1637 can be used to monitor the absence of oxygen on gas purity monitors such as nitrogen or argon. This version has also been used to monitor areas used by personnel that may become low in oxygen, the analyser can be set to alarm at 19% O2 thus preventing a health risk to those personnel.

Using a hypodermic needle to pierce the packaging, this device extracts a small gas sample, quickly measuring and displaying Oxygen and Carbon Dioxide concentration.

The Bluetooth® functionality allows for the device to be configured and monitored wirelessly from a PC running the provided Bluetooth® PC interface. It allows the device's sample history to be quickly downloaded to PC for review and archiving.

The analyser is designed for either ‘sample and hold’ measurement of modified atmosphere packaging or can be plumbed for continuous monitoring.

The Novatech 1637-Mk II Oxygen and Carbon Dioxide Analysers are ideal for: Head-space analysis in closed packages, Head-space analysis in cans, Inert and sterile packaging and continuous process measurement.

Model 1737 Oxygen & Carbon Dioxide Analyser

The 1737 analyser is another instrument from Novatech for measuring Oxygen and Carbon Dioxide concentration in a sample of gas. It has been designed for use in the food packaging industry where products are packaged in a modified atmosphere of nitrogen and/or carbon dioxide. Gas is extracted from the packaging via a sample line fitted with a hypodermic needle. The needle is used to penetrate the food packaging and an internal pump draws the package atmosphere into the analyser to be measured.

The 1737 has several key features that offer the user distinct advantages over other gas analysers:

- The oxygen sensors can be tailored to suit the needs of the user

- The oxygen sensors are not wet electrolyte type so will not age

- The oxygen sensors are field replaceable

- An optional internal battery can be supplied allowing up to 1 hour of continuous operation without mains power.

- It has a large clear display

- All samples are stored in an internal log that can be easily reviewed by the operator

- It can be configured to read and log the samples based on a series of product requirements

- Samples can be uploaded to a computer using wireless technology

- Automatic calibration is done whenever the sample is coming from the air

- Extended CO2 calibration is an automatic display driven process

It is critical to control the consistency and quality of packaging materials and optimise the packaging process to reduce waste.