An Australian Water Authority has recently installed a Venturi-Aeration system from Hydro Innovations into a sludge storage tank to add dissolved oxygen, remove nutrients and mix the tank.

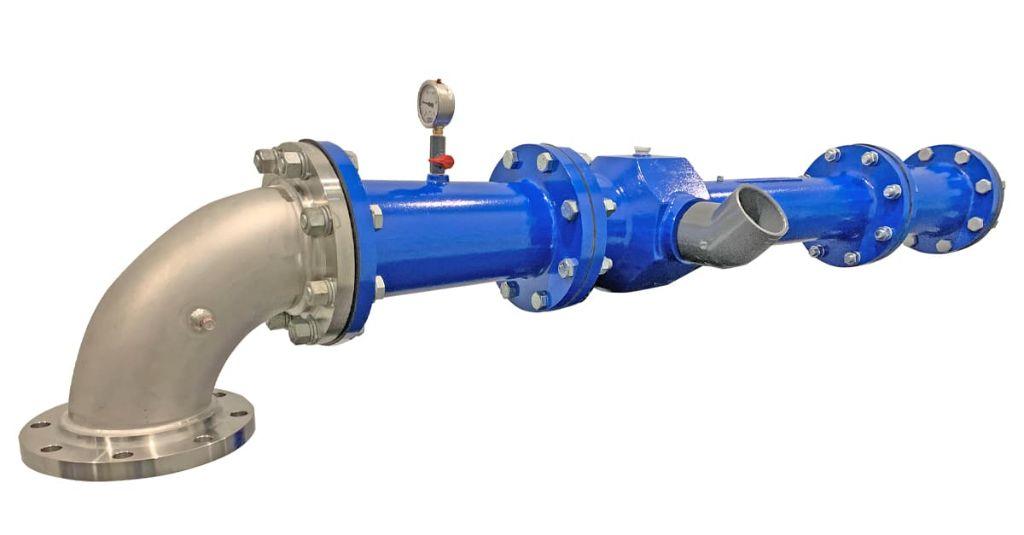

A Gorman-Rupp Super T Series pump was used with a 30kW motor to “drive” the Venturi-Aerator, and the unit was set up to discharge several metres below the surface. All of the aeration equipment [pump and venturi unit] is located on the outside of the sludge tank, giving operators quick, safe and easy access to the equipment for monitoring. It is also convenient for operators to perform routine maintenance to ensure a long service life for the system.

The system works using Bernoulli’s principle, whereby a decrease in pressure is caused by increasing the speed of a fluid. The Gorman-Rupp pumps draws fluid from the tank [or lagoon or basin] to be treated, then discharges it into the Venturi-Aerator, where a nozzle accelerates it up to 16 metres per second. This increase in velocity creates a low-pressure area within the Venturi unit, enabling atmospheric air to be drawn into the unit where water and air are mixed under pressure. The effluent is then discharged, saturated with dissolved oxygen. The venturi unit has no moving parts.

Venturi-Aerators are available in four sizes [50mm, 75mm, 100mm and 150mm], enabling the delivery of up to 30kg of dissolved oxygen per hour. Multiple units are used where more oxygen is required. For large applications, larger single pumps can be used to pressurise multiple Venturi-aerators.

The Water Authority was very particular in specifying parameters for the system to meet, and rate the unit as delivering good performance, ensuring aerobic conditions are maintained. Their average dissolved oxygen levels of up to 1.3mg/L are being maintained and ammonia nitrogen and phosphorus levels are less than 1.0mg/L.

Contact Hydro Innovations for more information on these units.

-160x160-state_article-rel-cat.png)

-205x205.jpg)