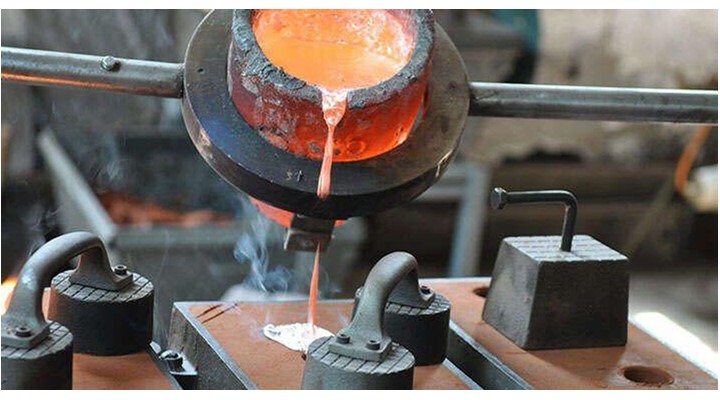

Aluminium is used in many different industries, such as construction, transportation, and food as it forms alloys with many materials. This versatility and light weight make aluminium and its alloys especially good for industries where losing weight is important, such as automotive and aerospace.

Yet aluminium casting is far from straightforward. Careful control of the elements within the melt is essential if the final material is to have the required properties. The most effective way of melt control is analysis with optical emission spectroscopy (OES). However, not all OES instruments are equal, and you need to be especially careful with aluminium as some of the elements that must be controlled to extremely low limits may not be detected by some analyzers.

The new OE720 spark spectrometer from Hitachi High-Tech is designed to deliver high-performance at a mid-range price. This means that elements that normally require a specialist instrument, such as phosphorus and antimony, can be detected at low detection limits by the OE720.

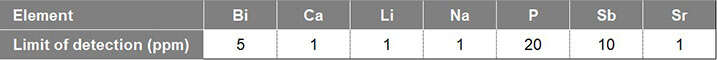

Detection limits of the OE720 for elements important to aluminium melt control

The newly designed optical system of the OE720 analyzer gives next-level optical resolution, and the CMOS detector technology ensures that a wide range of elements can be detected at extremely low limits. This means that phosphorus can be detected down to 20 ppm in near eutectic and hyper-eutectic aluminium-silicon alloys, and antimony, bismuth, lithium, strontium, and sodium can be controlled, ensuring optimal structural modification.

This high-performance capability allows you to verify that the tramp elements P, Ca, Bi and Sb within the aluminum melt meet the 120 ppm maximum combined total.

Performance of the OE720 for key aluminium elements:

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)