The End user

Camtek’s customer, Ensign Energy is a global leader in drilling and servicing wells, working in the world’s most extreme conditions. They offer powerful solutions and a full slate of land-based services for oil, gas and geothermal energy. Their Australian head office is based in South Australia, with approximately 360 staff.

Part of their business model is the initial set up and tapping of oil & gas wells. Rigs are assembled on site at the beginning of the project and upon completion dissembled and sent onto the next job. The camera system used on the rig system originated from Houston, Texas. Over the years Ensign (Aus) found the fault rate increasing due to the aging equipment. Repairs could only be made through the original manufacturer in the USA which impacted business due to downtime of the rig, the expense of the repairs plus significant shipping costs due to the need for a quick turnaround. The Australian division decided to find a local service provider to maintain the cameras to mitigate some of the costs. Camtek became the supplier of choice.

The business challenge

Camtek initially repaired the aging analogue CCTV cameras but found sourcing the out of date components difficult creating longer wait times, plus the lack of availability also meant they were expensive.

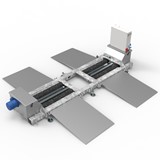

Camtek recommended replacing the entire system to a single cable (POE) IP based CCTV system to resolve these issues. There were also additional benefits of an IP system including much higher image quality, ability to remotely move and zoom specific cameras, improved motion detection, object removal detection, real time alerts and remote access to live and recorded images.

The CCTV solution is designed specifically for permanent video monitoring of all drilling operations. The cameras provide an overall view of all critical areas, and thus help to improve safety and operational efficiency.

The replacement CCTV system needed to be certified to IECEx zone 1 to meet the hazardous location (HL) requirements and offer a flexible installation process with simple ‘plug and play’ connections due to the nature of the rig being assembled on numerous sites.

Camtek were able to supply cameras but needed to find a partner who were able to supply a IECEx rated panel PC that was certified for the environment.

The APC ‘Value Add’

Rob commented, “My first step after initial contact was a visit to the APC Technology facilities. This gave me a clear understanding of their capabilities and services. It also gave me the opportunity to discuss the project with the engineering team in the early stages. I had initially thought we would need a stand-alone joystick to be able to navigate the cameras by the operator. This meant an additional item that would need to be rated for zone 1. APC did have a product which would fulfil our needs but instead of taking the easy route we discussed the possibility of a touchscreen that could enable this task to be done by a gloved operator on screen.”

“I found the APC team highly professional with a positive group mentality that enabled discussions to expand from the original scope and resulted in a solution that is currently one of a kind.”

Camtek partnered with APC and a third party software company to create the onscreen joystick. Though the design phase took longer, the return on investment included a reduction in overall capital expenditure and one less component to be rated for zone 1, increasing the safety of the system.

Rob commented on the first install. “During the project the staff at APC provided constant updates on progress and were on hand to assist right up to the installation of the system on site for the first time. Our install crew were able to resolve an issue because APC went above and beyond to ensure power supplies were shipped to site once a problem had been identified.”

End user feedback

Rob was able to provide feedback from the end user. “They found the image definition had massively improved both from the camera but also on the display. The touchscreen interaction also met and exceeded expectations notably because the move to an on screen joystick function was notably different from the previous generation and had raised some concerns with the operator about sensitivity.”

The future

The expected plan is to roll out the HL CCTV system to another six sites. The end user has been able to see the benefit of using Australian companies. They now have a cutting edge surveillance solution designed and manufactured within Australia resulting in a reduction in cost and time for all future maintenance requirements.

Rob commented, “We are looking forward to continuing our partnership with APC Technology and taking advantage of similar opportunities in Australia with this explosion-proof surveillance system. The open video system will allow us to provide customers with system solutions tailored to meet the need of their specific application.”

About Camtek Surveillance

Camtek Surveillance specialise in supplying and installing a wide range of surveillance equipment ranging from domestic and commercial CCTV & alarm installations to locally made commercial work site cameras. They also import/sell/service and distribute high end Industrial Intrinsically safe CCTV equipment including inspection cameras for the mining, plumbing and gas industry. Find out more about Camtek.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)