Organic compounds that absorb UV rays and inorganic compounds that provide a physical barrier and reflect UV light away from the skin. The metal oxides titanium oxide and zinc oxide are commonly used as reflective components. In modern products, these metal oxide particles are produced to a nanometer scale, which makes them transparent within the product. This means that many different products, such as make-up, can have a sun-protection element without altering the color of the product.

The effectiveness of the metal oxides to provide the level of protection required by the rating of the sunscreen or cosmetics depends on the amount of oxide present within the product, as well as the particle size and form. Therefore, controlling the metal oxide content during manufacturing is crucial in ensuring the sunscreen protects the consumer in the way claimed

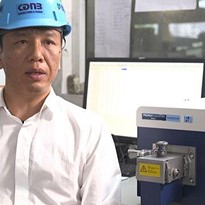

Benchtop XRF for rapid determination of TiO2 and ZnO

X-ray fluorescence (XRF) is an ideal technique for determining the level of titanium and zinc oxides in sunscreen and cosmetics as it’s completely non-destructive, fast, and requires very little sample preparation, even when the sample is in powder, cream or gel form.

Hitachi High-Tech’s X-Supreme8000 benchtop XRF analyzer makes routine analysis of sunscreen and other cosmetics easy. Designed for use in a busy production environment, the X-Supreme has several features that help when measuring high volumes of product that must meet exact specifications:

Powerful technology for accurate results

The X-Supreme contains a high-performance X-ray tube and a high-resolution silicon-drift detector (SDD). These work in tandem to ensure that accurate and precise results are obtained within minutes, with ZnO and TiO2 being measured simultaneously.

To increase accuracy even further, the X-Supreme8000 includes a sample spinner than rotates the sample to allow for several measurements to be taken over the sample’s surface. This reduces the effect of sample inhomogeneity and helps to ensure repeatable results.

Easy to use

To measure a sample, all you need to do is pour the liquid into a sample cup, place it in the analyzer and close the lid. Simply type in the sample’s name for future reference and press the button to begin a scan. The results are displayed within seconds on the large, industrial-grade touch screen. It’s possible to set the software to show a simple pass or fail message, which helps to reduce errors when interpreting results, especially when dealing with many samples.

Robust enough for a production environment

An XRF analyzer is a high-precision instrument and the X-Supreme has many safety features that protect the delicate parts of the analyzer when in normal use. For example, a secondary safety window can be used under the sample cup to contain any potential leak. The X-Supreme also includes an integrated sample changer that makes sure the sample is in the path of the X-ray tube and detector only when a measurement is being taken and moves it away from these components as soon as the analysis is done.

The X-Supreme8000 is a powerful instrument that supports your sunscreen and cosmetics quality control program, ensuring that every batch meets the stringent specification demanded. The rapid analysis time, reliable results, and built-in safety features reduce downtime and increase testing efficiency.