The ability to visualise and interpret the invisible heat signatures emitted and objects has revolutionised industries ranging from manufacturing to fire fighting.

What where the early days of Infrared Radiation and Thermal Imaging Cameras?

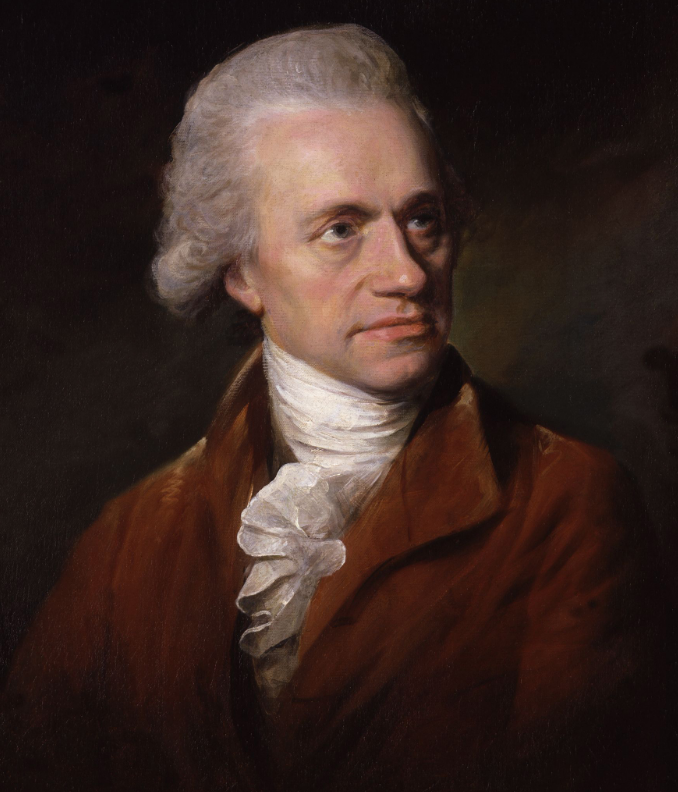

The thermal imaging works with infrared radiation, commonly referred to as IR or infrared light, a form of energy that is invisible to the human eye but is felt as heat. This phenomenon is an essential part of the electromagnetic spectrum, which encompasses a wide range of frequencies, each with its unique characteristics and applications. Discovered by British astronomer William Herschel in 1800, infrared radiation has since become a critical element in scientific research, technology, and everyday life.

The thermal imaging works with infrared radiation, commonly referred to as IR or infrared light, a form of energy that is invisible to the human eye but is felt as heat. This phenomenon is an essential part of the electromagnetic spectrum, which encompasses a wide range of frequencies, each with its unique characteristics and applications. Discovered by British astronomer William Herschel in 1800, infrared radiation has since become a critical element in scientific research, technology, and everyday life.

Herschel’s experiment led to the discovery of infrared radiation, while studying the temperature difference across the visible spectrum, the experiment showed a warmer temperature beyond the red end hence the birth of understanding IR radiation.

Infrared extends our vision beyond visible light, allowing us to explore the heat energy emitted by objects. Technology advancements in infrared CCD imaging systems (A charge-coupled device  (CCD) is a light-sensitive integrated circuit that captures images by converting photons to electrons. A CCD sensor breaks the image elements into pixels.)

(CCD) is a light-sensitive integrated circuit that captures images by converting photons to electrons. A CCD sensor breaks the image elements into pixels.)

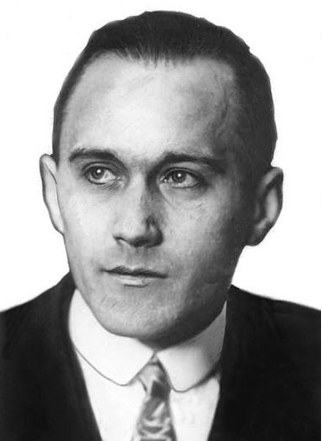

The thermal imaging concept emerged in the early 20th century, in 1929 Hugarian physicist Kálmán Tihanyi invented the world’s first infrared-sensitive (night vision) electronic television camera for anti-aircraft defence in Britian.

The Evolution of Thermal Imaging Cameras.

As technology advanced so did the thermal imaging cameras, each advancement offered something new to the generations of thermal imaging cameras. Improvements in sensitivity, resolution, efficiency, and applications.

Infrared (IR) technology has revolutionized various industries, from manufacturing industry, plumbing, pest control, surveillance to healthcare and automotive applications. Within the realm of infrared imaging, two main categories of camera cores have emerged: uncooled and cooled infrared camera cores. These cores are the heart of infrared cameras, determining their performance and capabilities.

Infrared (IR) technology has revolutionized various industries, from manufacturing industry, plumbing, pest control, surveillance to healthcare and automotive applications. Within the realm of infrared imaging, two main categories of camera cores have emerged: uncooled and cooled infrared camera cores. These cores are the heart of infrared cameras, determining their performance and capabilities.

The fundamental distinction between uncooled and cooled infrared camera cores lies in their cooling mechanisms. Cooled camera cores employ advanced cooling techniques, often involving cryogenic cooling, to reduce the temperature of the sensor. This cooling significantly enhances the sensitivity of the camera by reducing the thermal noise generated by the sensor itself. On the other hand, uncooled camera cores operate at ambient temperatures, relying on the sensor design and electronics to compensate for the thermal noise.

The cooling mechanism directly affects the sensitivity of the infrared camera core. Cooled camera cores, due to their reduced sensor temperature, exhibit higher sensitivity. This heightened sensitivity allows them to detect even the slightest temperature differences in the observed scene. This is especially crucial in applications where identifying subtle thermal variations is essential, such as in manufacturing industries, military reconnaissance, scientific research, and certain industrial processes. Uncooled camera cores, although less sensitive than their cooled counterparts, still offer respectable performance in various applications.

The cooling mechanisms in cooled camera cores contribute to their larger size and heavier weight compared to uncooled cores. The presence of cryogenic cooling systems and additional  components necessary for maintaining low sensor temperatures increases the overall bulk of the infrared camera core. This size and weight disadvantage can limit the portability and flexibility of cooled cameras, making them less suitable for handheld or mobile applications. Uncooled camera cores, due to their lack of cooling systems, are generally more compact and lightweight, which is advantageous in scenarios where space and weight considerations are paramount.

components necessary for maintaining low sensor temperatures increases the overall bulk of the infrared camera core. This size and weight disadvantage can limit the portability and flexibility of cooled cameras, making them less suitable for handheld or mobile applications. Uncooled camera cores, due to their lack of cooling systems, are generally more compact and lightweight, which is advantageous in scenarios where space and weight considerations are paramount.

The choice between uncooled and cooled infrared camera cores depends on the specific application requirements. Cooled camera cores find their niche in high-end applications where sensitivity and precision are crucial. These applications include long-range surveillance, scientific research, thermal imaging in extreme conditions, and military targeting systems. The enhanced sensitivity of cooled cores makes them well-suited for detecting hidden objects, monitoring wildlife, and conducting detailed thermal inspections.

On the other hand, uncooled infrared camera cores are versatile and find use in a wide range of applications. They are commonly employed in commercial security systems, building inspections, firefighting, automotive night vision, and medical diagnostics. Uncooled cores are particularly valuable in applications that demand cost-effectiveness and portability without compromising on performance.

What are the vital Specifications of a thermal Imaging Camera?

The vital specifications of a thermal imaging camera are essential for harnessing their true potential. From pixel pitch to frame rate, each specification plays a crucial role in enhancing the performance and accuracy of thermal imaging.

The vital specifications of a thermal imaging camera are essential for harnessing their true potential. From pixel pitch to frame rate, each specification plays a crucial role in enhancing the performance and accuracy of thermal imaging.

Pixel pitch refers to the distance between individual pixels on the thermal sensor. Smaller pixel pitch means higher pixel density, resulting in more detailed thermal images. Each pixel captures temperature information, and a smaller pixel pitch allows for better spatial resolution and accuracy. Pixel pitch directly affects the camera’s spatial resolution. With a smaller pixel pitch, the camera can detect smaller temperature variations and present a more detailed image. A thermal imaging camera with a smaller pixel pitch provides enhanced image clarity, making it ideal for applications requiring precise temperature measurement and identification of fine details.

Resolution is a crucial specification that determines the total number of pixels in the thermal image. Higher resolution means more pixels, resulting in sharper and more defined thermal images. Thermal imaging cameras come with varying resolution options, such as low, medium, and high. High-resolution cameras are suitable for applications that demand superior image quality and detailed analysis.

NETD (Noise Equivalent Temperature Difference) is a measure of the sensitivity to detect small temperature differences. A lower NETD value indicates better sensitivity and higher thermal contrast. A thermal imaging camera with a lower NETD value is better equipped to identify minor temperature changes, making it more suitable for applications that involve detecting subtle thermal anomalies.

NETD (Noise Equivalent Temperature Difference) is a measure of the sensitivity to detect small temperature differences. A lower NETD value indicates better sensitivity and higher thermal contrast. A thermal imaging camera with a lower NETD value is better equipped to identify minor temperature changes, making it more suitable for applications that involve detecting subtle thermal anomalies.

FOV (Field of View) is the area that the thermal imaging camera can capture in a single frame. A wider FOV covers a larger area, while a narrower FOV focuses on a smaller target region. They offer various FOV options, including wide-angle, narrow, and zoom. Each FOV type caters to different applications, such as surveillance, inspections, and research.

Where do we use thermal imaging?

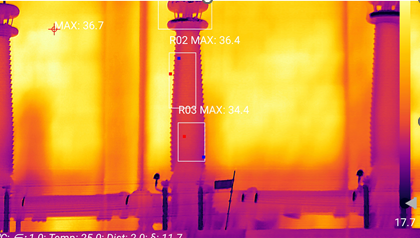

Electrical maintenance uses for thermal imaging are extensive. For example, power line technicians use thermal imaging to locate and pinpoint joints and parts that are at risk of overheating as they’re already emitting more heat than the stronger sections. They can also help spot loose connections or devices that are starting to fail. Pyrosales offer the InfiRay C series or M series which is best for this industry.

Electrical maintenance uses for thermal imaging are extensive. For example, power line technicians use thermal imaging to locate and pinpoint joints and parts that are at risk of overheating as they’re already emitting more heat than the stronger sections. They can also help spot loose connections or devices that are starting to fail. Pyrosales offer the InfiRay C series or M series which is best for this industry.

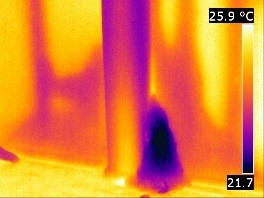

Plumbers use thermal imagers to inspect sites of possible leaks, mainly through walls and pipes. Since the devices can be used at a distance, they’re ideal for finding potential problems in equipment that is either hard to reach or might otherwise pose safety issues to workers. Pyrosales offer the InfiRay C series or M series which is best for this industry.

Plumbers use thermal imagers to inspect sites of possible leaks, mainly through walls and pipes. Since the devices can be used at a distance, they’re ideal for finding potential problems in equipment that is either hard to reach or might otherwise pose safety issues to workers. Pyrosales offer the InfiRay C series or M series which is best for this industry.

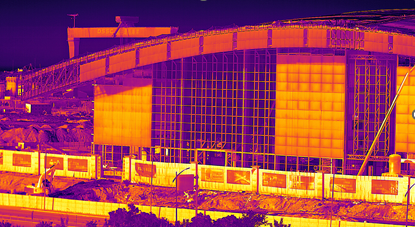

Mechanical and building construction technicians who work with thermal insulation use imaging to quickly identify leaks, which is important to maintain efficient temperature regulation in a building. At a glance, they can analyse a building’s structure and spot faults. Heat loss from walls, HVAC equipment, doors and windows are common thermal performance issues that are easily picked up by a thermal imager. Pyrosales offer the InfiRay C series or M series which is best for this industry.

Mechanical and building construction technicians who work with thermal insulation use imaging to quickly identify leaks, which is important to maintain efficient temperature regulation in a building. At a glance, they can analyse a building’s structure and spot faults. Heat loss from walls, HVAC equipment, doors and windows are common thermal performance issues that are easily picked up by a thermal imager. Pyrosales offer the InfiRay C series or M series which is best for this industry.

Animal and Pest management is a field which has a surprising number of uses for thermal imagers. They can help spot pests or animals in dark roof areas without having to climb up into them, and they can detect potential termite activity. Also, they’re commonly used to conduct wildlife surveys more easily in a totally non-invasive, non-intrusive manner. Pyrosales offer the InfiRay C series or M series which is best for this industry. View M620 Series Data Sheet View M600 Series Data Sheet.

Animal and Pest management is a field which has a surprising number of uses for thermal imagers. They can help spot pests or animals in dark roof areas without having to climb up into them, and they can detect potential termite activity. Also, they’re commonly used to conduct wildlife surveys more easily in a totally non-invasive, non-intrusive manner. Pyrosales offer the InfiRay C series or M series which is best for this industry. View M620 Series Data Sheet View M600 Series Data Sheet.

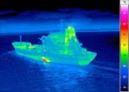

Transport navigation gets significant benefits from thermal imaging, particularly when traveling at night. For example, maritime navigation uses it for clearly seeing other vessels, people, and obstructions during the night while out at sea. In recent years, cars have begun incorporating infrared cameras to alert drivers of people or animals beyond streetlights or the reach of their headlights. Pyrosales do not stock this product for this industry, but we can assist.

Transport navigation gets significant benefits from thermal imaging, particularly when traveling at night. For example, maritime navigation uses it for clearly seeing other vessels, people, and obstructions during the night while out at sea. In recent years, cars have begun incorporating infrared cameras to alert drivers of people or animals beyond streetlights or the reach of their headlights. Pyrosales do not stock this product for this industry, but we can assist.

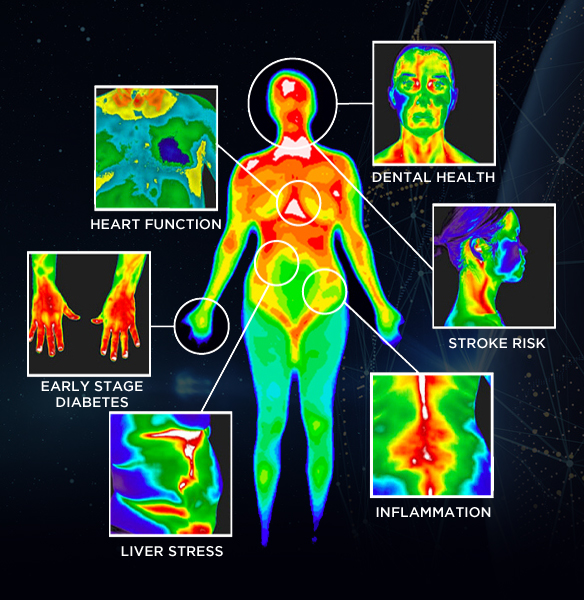

Healthcare and medicine also have practical uses, such as to spot fevers and temperature anomalies. This has proven to be especially important in airports where these thermal imaging cameras can quickly and accurately scan all incoming or outgoing passengers for higher temperatures, which was crucial during recent outbreaks of diseases like SARS and Ebola. Additionally, thermal imagers have been proven to help diagnose a range of disorders associated with the neck, back and limbs, as well as circulatory problems. Pyrosales do not stock this product for this industry, but we can assist.

Healthcare and medicine also have practical uses, such as to spot fevers and temperature anomalies. This has proven to be especially important in airports where these thermal imaging cameras can quickly and accurately scan all incoming or outgoing passengers for higher temperatures, which was crucial during recent outbreaks of diseases like SARS and Ebola. Additionally, thermal imagers have been proven to help diagnose a range of disorders associated with the neck, back and limbs, as well as circulatory problems. Pyrosales do not stock this product for this industry, but we can assist.

Fire-fighters use thermal imaging to help them see through smoke, particularly in rescue missions when they’re searching for people in an otherwise obscured and dangerous environment. They also use thermal cameras for rapid identification of spot fires, so they can intervene before they spread. Pyrosales do not stock this product for this industry, but we can assist.

Fire-fighters use thermal imaging to help them see through smoke, particularly in rescue missions when they’re searching for people in an otherwise obscured and dangerous environment. They also use thermal cameras for rapid identification of spot fires, so they can intervene before they spread. Pyrosales do not stock this product for this industry, but we can assist.

Police and law enforcement agencies incorporate thermal imagers into their surveillance equipment, used for locating suspects especially at night, as well as to investigate crime scenes and for search and rescue operations. They’re superior to night-vision devices, as they don’t require any ambient light and are unaffected by bright lights, which is essential for tactical missions. Pyrosales do not stock this product for this industry, but we can assit.

Police and law enforcement agencies incorporate thermal imagers into their surveillance equipment, used for locating suspects especially at night, as well as to investigate crime scenes and for search and rescue operations. They’re superior to night-vision devices, as they don’t require any ambient light and are unaffected by bright lights, which is essential for tactical missions. Pyrosales do not stock this product for this industry, but we can assit.

Science and research are undoubtedly sectors that draw significant benefits from using thermal imagers, for accurate and precise visualisations of heat patterns such as dark side of the moon.

Other applications which use a thermal imaging camera include heating, ventilation and air conditioning installations, mould detection, quality assurance in processes such as glass manufacturing and many more.

Other applications which use a thermal imaging camera include heating, ventilation and air conditioning installations, mould detection, quality assurance in processes such as glass manufacturing and many more.

Money saving is something you wouldn’t necessarily expect from a thermal imaging device, but when you think about everything it can do, it makes sense. After the upfront cost of purchasing the device, they can undoubtedly save your business or home thousands of dollars or more in potential maintenance and repair costs that might incur if faults, leaks, or weaknesses were not identified earlier.

However, it’s important to recognise that while thermal imaging has all these applications, it’s often best to use additional instruments or tools when appropriate to confirm what you’re seeing. Additionally, it’s worth noting that thermal imaging cameras are unable to see through walls and objects, but rather, they only pick up what’s reflected off them.

Choosing and purchasing a high-quality thermal imaging Camera

It’s crucial to use a high-quality product to ensure that you detect and record accurate measurements. A big difference between different types of thermal imagers are the resolution and clarity of the images they provide.

It’s crucial to use a high-quality product to ensure that you detect and record accurate measurements. A big difference between different types of thermal imagers are the resolution and clarity of the images they provide.

Here at Pyrosales we are proud to offer a wide range of Thermal imaging Cameras suitable for all kinds of applications, whether they be professional or hobbyist. Our suite of top-range thermal imagers is made by InfiRay, a globally active, high-tech company with an expertise in innovative measurement solutions that are guaranteed to meet your needs.

Thermal imaging is an impressive and compact method of identifying, measuring and visualising heat patterns, particularly in environments where there’s a lack of visible light. Armed with an effective and high-quality thermal imaging camera, there are a broad range of applications available, from industrial to health to research and science and so much more.