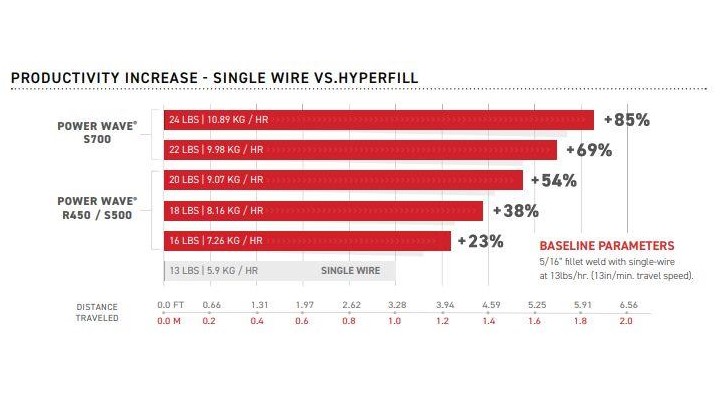

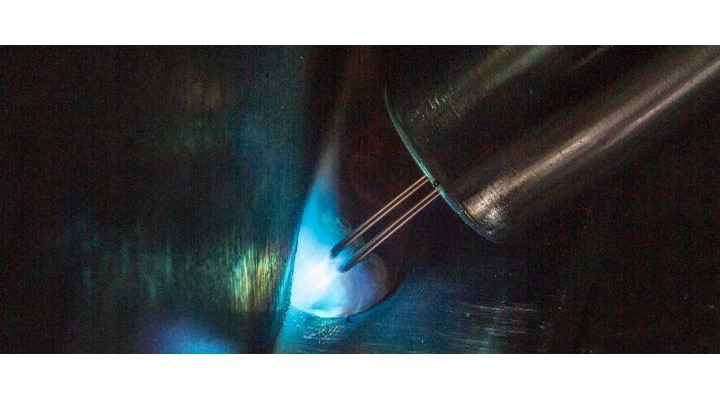

Designed to revolutionize heavy fabrication productivity, the patent-pending HyperFill twin wire MIG solution allows for increased deposition rates without compromising puddle stability or weld quality. Utilizing a single power source, a single wire feeder, and a single tip, this innovative twin wire design delivers a wide, smooth arc done that allows for deposition rates above 18lbs/hr | 8 kg/hr. (24+ lbs/hr. | 10.8 kg/hr robotic) without added system or operator complexity.

Single Wire VS Hyperfill

Single Wire:

- Generates a deep, narrow arc cone.

- Arc stability deteriorates at higher wire feed speeds making process more difficult to use.

- Narrow arc cone, narrow penetration profile. Increased risk of weld defects at higher deposition rates.

Hyperfill:

- Generates a wide, evenly distributed arc cone.

- Smooth, stable puddle is more favorable and makes process easy to use at higher deposition rates

- Wide arc cone leads to favorable, robust penetration profile and helps to improve weld quality at high deposition rates.

-205x205.jpg)